John, I set my drill dr to 118 degrees on the bevel...where you actually do the grinding, then I set the chuck, the part with the notches one notch down from 118. You will see 118 in the center of it, then + and - signs, try one notch down or subtracted from 118, probably closer to 116.

I had the same trouble but I played with it for a long time. Finally come up with this setting and works very well on mild steel. If your bits come out with a different angle it might take more grinding before its right. Look at the grind and make sure the bit is shiny all the way across the flank as in the pic. If not the bit used is of a different angle. Normally the point angle is what is different.

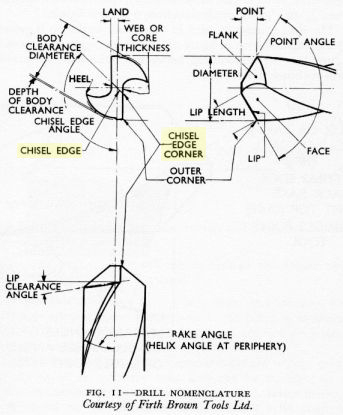

When hand sharpening, my students have the most trouble getting the chisel and the lip angle right. The bit will just sit on top of the metal if those are not right.

There are many different pics of drill bit nomenclature, some call the pieces different things, this one is similar to the one I use in class.