One of the advantages of a circular tank is it's self cleaning ability. And that is the major reason I use them. In square or rectangular tanks solids can collect in corners and be difficult to remove. Usually not is issue with tilapia, as one can purposely keep it in suspension to remove, but other species aren't as tolerant. Or you can spend time removing the solids manually.

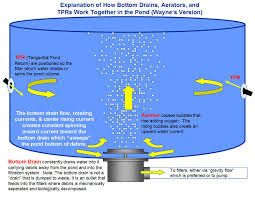

A circular flow can be set up to cause settleable solids (feces and uneaten feed) to move toward a drain in the center of the tank. (Known as centripetal flow or the tea cup effect). This is done by creating an inflow that is tangential to the inside wall of the tank. Koi pond folks call them TPR's. (Tangential Pond Return.) More in another thread.

Or one can alternately mount a diffuser directly above the drain which pushes up water, and pulls it back down the outside edges of the tank and then to the center drain. Or one can do both. I prefer to do both. Obviously the diffuser has a dual effect of adding oxygen to the water.

Here is an illustration of how that works, although my airline comes into the top of the tank and my return flow is a DIY mounted spray bar with a vertical and horizontal axis. (To be covered later).

In this thread I'll concentrate on the center drain, but it was important to explain the above to show what role the center drain has in a circular tank, how you can build it yourself, and how it works to collect solids or at least pull them out periodically when a knife gate valve is opened.

Solids in a tank consist of settlable solids AND suspended solids. Both consist of waste products produced by the fish an uneaten feed. A good system will remove these as soon as possible, as they not only are a conduit for bacteria, but can irritate the gills of fish. The center drain is my vehicle to remove settleable solids. To be covered later I use a PVC siphon to remove the suspended solids and settleable solids that have not settled via gravity.

I make my center drains out of a 3 inch PVC shower drain or a vent cap. I prefer the vent cap when I have very small fish as they may be sucked out with the shower drain. Both can be purchased at hardware stores or big box store like Menards or Home Depot and will be glued inside a 3 inch PVC pipe.

Two different size vent caps that can be used as a drain. A shower drain:

A shower drain:

I first glue a PVC end cap on a section of 3 inch PVC with PVC glue, and let the glue cure overnight.

Then come back with a chop saw and cut most of the cap off to leave a retainer ring on the outside of the 3 inch pipe

Then come back with a chop saw and cut most of the cap off to leave a retainer ring on the outside of the 3 inch pipe.

Here is the result:

Here's a 3 inch shower drain glued into the PVC pipe also showing the retainer ring.

Here's a 3 inch shower drain glued into the PVC pipe also showing the retainer ring.  Inside view of shower drain glued to PVC pipe section:

Inside view of shower drain glued to PVC pipe section:

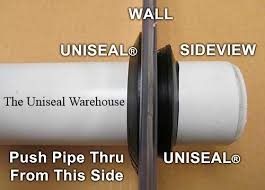

Since I prefer to use a Uniseal vs. a bulkhead fitting to install the drain and pipe, this glued on retainer ring keeps the shower drain or vent cap from slipping through the Uniseal. The original lip on both drains isn't quite wide enough to prevent that.

If you're not familiar with a Uniseal they are a type of fitting that looks like this.

They are made of a MPR, rated to 40 psi, and warranted for 25 years. They are immune to cold, will not harden, and hold pressure and vacuum. They fit PVC pipes from 1/2 inch to 6 inches. You can use them on curved surfaces like plastic drums and other PVC pipe. However I do prefer a bulkhead fitting is if I want to place a fitting in the bottom of a drum and it has a high seam line there. A downside to unseals are they are limited to material 1/2 inch thick or less. Most plastic tanks are 1/2 inch or less though. And you must make a precise hole with a hole saw.

I also prefer a Uniseal because it's much cheaper than bulkhead fitting of the same size, and it doesn't create the profile a bulkhead fitting makes, in the the bottom inside of the tank, where settleable solids can get trapped up against it.

Here is what they look like when installed in a tank wall:

When the pipe is shoved through the fitting expands to make a water tight seal.

An appropriate size hole is cut for a 3 inch Uniseal (4 inch hole saw). Unlike a bulkhead fitting the hold has to be precise with no irregularities.

Next I grind down the edge of the other end of the pipe to fit through the Uniseal to a make it possible for the pipe to fit through. I also rub vaseline on the pipe. Otherwise if is very difficult to slide the pipe through. It's a very tight fit which does NOT leak.

I insert the Unseal with the wide side up and then push the pipe in as much as I can with my hand. Standing on the drain if the tank is elevated should push it in all the way to the retainer ring you created.