|

Forums36

Topics40,963

Posts557,976

Members18,503

| |

Most Online3,612

Jan 10th, 2023

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |

As we continue to develop our pondsite from scratch, I thought it might be the better decision to split out the launch and dock construction under a separate thread. This way, anyone looking for information for the specific category won't get lost in the pond construction stuff. I have transferred the beginning presentation of the subject from the Principal Spillway Logic thread to this thread and will follow it's development here. If there is a chance that I can pay back the PB forum support crew by helping just one other brethren, then this thread will have served a good purpose. - - Well, on to the next project; the concrete work for 2 docks and a boat launch. Jeesh, another reflection on the work that concrete guys do...truly more new-found respect! We have formed up the first pour of the launch. The rebar is laid within the forms, but not yet tied and put up on the bar chairs.  We have drilled ten 12" dia holes for the concrete piers that will support the dock that borders the launch for 44 feet with a 14' x 16' covered deck at the end. We have also installed small rebar cages within the concrete pier forms for added stability.  There another 8 more of these holes at the beach area for a smaller 20' x 12' "L" shaped dock. The 20' section runs along the edge of the sand beach (recommended by Ewest), and the 12' "L" section turns away at 90 degrees into a quick drop-off that will put it into 6-7 ft of water...a great place to temporarily tie up the Liberty Ferry. Oh yeah...we aren't hurtin' for rain, either. The banks are runnin' little erosion channels and the rye is just startin' to sprout. Nothing too severe and we really got a gully washer a couple of days ago. The 1 acre area in front of the dam has about 4-5 feet of water. We gotta hustle up this concrete work and shift to the tire pyramids and PVC tree structures. The race with Mother Nature is on. - - (OK...now on to the new stuff...)

|

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |

Before I continue, allow me to throw out some specifications and logistics.

The pondsite is at the end of a 2000 ft entry drive that was blazed last year. The last leg of this entry is about 200 ft, straight, and into the east end of the pond at a gradual slope. We knew right away that it would serve well as a boat launch. The launch will be 72' long, 12' wide, and about 6 - 7" thick. At the end of the launch, the normal pool water depth will be 5 feet. The launch is reinforced with #3 epoxy coated rebar (3/8" dia) set at 12" on-center, each way. They are set on bar chairs to elevate them. Rebar is too thick and heavy to reach into the concrete, during the pour, and just pull up from flat on the ground, like wire mesh. We are pouring the launch in sections, the first two will be 31' long. This was selected because we are using 16' long lumber for the forms AND the sides are really not accessible for a concrete truck so the pour must be done from the end. The chutes on the trucks only reach out about 20 feet or so. We used 2 x 6 for the forms. The form at the top of the pour (where the next pour will attach and continue) is drilled out with 2" dia holes at 12" o.c. and 3/4" x 18" epoxy coated dowels are laid in half way into the form zone. They will harden within the concrete, and the larger dia 2" holes should allow us to still remove the 2 x 6 form. These dowels will tie the next pour to the previous.

The round concrete piers are drilled with a 12" dia bit. They all average 48" long from the base of the hole to the top of the tube. The holes within the water are not as deep within the soil since frost heave should not be a problem there. They are, tho, drilled thru the topsoil and into the clay below for a firm bearing surface. Each hole is reinforced with a cage of epoxy coated rebar that is 4 verticals with 4 square ties of #3 rebar. The cages were pre-fab'd in the cool of the basement and the the vertical members were manufactured long. I trimmed these vertical members to length, on site, to be 8" longer the actual depth of each hole as we drilled them. This was done because the hole depths did vary somewhat. Then, each cage was set within the tube/hole and pounded with a 3# sledge until the entire cage was about 2" below the top of the tube. This centralized and stabilized the cage for the concrete pour.

|

|

|

|

|

Joined: May 2004

Posts: 234

Lunker

|

Lunker

Joined: May 2004

Posts: 234 |

Nice documentation. More pictures! More Pictures!  Ed

|

|

|

|

|

Joined: Sep 2003

Posts: 13,750 Likes: 295

Moderator Ambassador Field Correspondent Hall of Fame 2014  Lunker

|

Moderator Ambassador Field Correspondent Hall of Fame 2014  Lunker

Joined: Sep 2003

Posts: 13,750 Likes: 295 |

Brettski, I see some water there!

Has the urge to put in a few dozen fatheads overcome you yet???!!!!!!!

Excerpt from Robert Crais' "The Monkey's Raincoat:"

"She took another microscopic bite of her sandwich, then pushed it away. Maybe she absorbed nutrients from her surroundings."

|

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |

...Sunil identifies temptation: Brettski, I see some water there!

Has the urge to put in a few dozen fatheads overcome you yet???!!!!!!! ...No, not yet. I have my hands full with these other priority projects....but....a couple more good rains, a few more weeks of construction progress, ....? - - We elected to cut the verts on the rebar cages on-site since I was unsure as to the actual depths of each...no biggie. I went to Menards and purchased their largest bolt cutter; a unit 30" in length. I went home and did a test-run on a pc of rebar on the garage floor. Now remember, this is Grade 60 rebar; the good stuff. It also makes it harder to cut. After leaning, pumping, and re-adjusting the cut, the rebar finally yields with a high-pitched "ping" and shoots across the concrete floor like a bottle rocket. This ain't gonna git it in the dirt at the jobsite. Time for some re-engineering. I took a piece of 2 x 8 x 16" treated pine and milled a slot for the handle grip (radial arm saw). Then I cut slots thru it for 2 larger hose clamps and cranked the whole thing together to create a stabile base. Then I added a piece of chain-link fence post pipe that I had in stock.  Huge improvement. Still a bear to crank it down and cut, but manageable. Still got the high velocity "ping"  . - - The rebar mat was laid out on the ground in their respective positions. I laid the long bars first, then tied the short cross pieces one at a time. I could only do one at a time because they would roll downhill on the long bars like they were rails. Next pour, we go the opposite way :rolleyes: . I ain't no iron-worker, nor do I play one on TV, but I did stay at a Holiday Inn Express last night! We used standard issue 16 ga. annealed tie wire. I tied every junction at the perimeter to stabilize the mass. Then we hop-scotched the entire mat, adding a tie so that no tie was any further than 36" from another. Why not all of 'em?....you try it. We then elevated the mat by placing a rebar chair at about 48" o.c. They are also standard issue 3" bar chairs; a plastic cone (like a volcano) with the sides cut out for concrete permeation and round notches at the top rim to accept the rebar.  We had areas near the edges that went pretty deep. I decided it was easier to fill the gap with concrete over terra-firma as opposed to filling the holes with loose soil and compacting. In these areas, we boosted the chairs with larger rocks. At the last minute, as we rested for a couple of minutes and waited for the concrete truck, I decided that maybe I should put a tie wire thru each of the chairs and tie it to the mat. Whew...good call, Brettski. When the force of the pour hits 'em, another 11th hour decision yields good results. Oh yeah, the 3/4" x 18" smooth dowels....I cut 2" dia holes at 12" on center in the 2 x 6" form, then screwed on the backer blocks you see with 7/8" dia holes. This centralizes the bars within the 2" holes behind them.  When we go to strip the forms, remove the screw-on blocks and hopefully pop off the 2 x 6 form. The 2" holes in the form should allow room to slip over the dowels, since they are not absolutely square and straight. - - Then, the pour. Boy am I glad that I bought (and brought) those waders! The entire slab took about 9 yards of concrete.  - - Donna-ski and I struck it off with a 2 x 6 x 14', using the standard sawing motion. PLEASE NOTE: Donna-ski is one tough dame. I laugh to think that she could kick most of my buddie's butts. She takes pain pills for some bad knees and still scares me. Anyway, the beauty of finishing a boat launch is that the goal is a non-skid, non-slip surface. That, and most of it is below the water, puts the finishing portion well within our DIY grasp. After we strike it off, that's it...it ain't real pretty, but looks OK for novices. Then I put the finishing touch to it  I took a garden rake and worked from each edge, dropping it in the center and drawing it back out, scraping up the top aggregate and creating the ultimate non-skid surface:  I got your broom finish right here!

|

|

|

|

|

Joined: Sep 2003

Posts: 13,750 Likes: 295

Moderator Ambassador Field Correspondent Hall of Fame 2014  Lunker

|

Moderator Ambassador Field Correspondent Hall of Fame 2014  Lunker

Joined: Sep 2003

Posts: 13,750 Likes: 295 |

Sometime in the future, you're gonna have to let us know how much this all cost you.

I could not help myself but to swing by the local bait store and buy 3 dozen fatheads (assuming they were true fatheads) and throw them into that water.

I know Guvnor Davidson would do the same.

Excerpt from Robert Crais' "The Monkey's Raincoat:"

"She took another microscopic bite of her sandwich, then pushed it away. Maybe she absorbed nutrients from her surroundings."

|

|

|

|

|

Joined: May 2004

Posts: 13,974 Likes: 277

Moderator Lunker

|

Moderator Lunker

Joined: May 2004

Posts: 13,974 Likes: 277 |

Originally posted by Sunil:

Sometime in the future, you're gonna have to let us know how much this all cost you.

Be sure and do so only by PM, utilizing encryption. This is one instance where violating the DLYHKHMTPC/DLYWKHMTPC rule, in the open forum, could cost hundreds of lives.  Great pics and tutorial, Brettski.

"Live like you'll die tomorrow, but manage your grass like you'll live forever." -S. M. Stirling ![[Linked Image from i.pinimg.com]](https://i.pinimg.com/736x/ed/b5/e7/edb5e7f935843b996cf52be593c9ebd2--smoothie-smooth-collie.jpg)

|

|

|

|

|

Joined: Feb 2005

Posts: 4,025 Likes: 1

Lunker

|

Lunker

Joined: Feb 2005

Posts: 4,025 Likes: 1 |

Originally posted by Sunil:

Sometime in the future, you're gonna have to let us know how much this all cost you.

I could not help myself but to swing by the local bait store and buy 3 dozen fatheads (assuming they were true fatheads) and throw them into that water.

I know Guvnor Davidson would do the same. Maybe it cost enough that he cant afford any fatheads. :p ...but, it is one helluva job. Brettski, you're my hero.

|

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |

Thanks, guys...now the big faux-pah!

PFF just PM'd me and quizzed me on the drop of the grade vs the length. He noted that a 72' long launch that drops 5' would "put water into the truck doors before the boat floats". First I geeked out, then I remembered that about 20' is exposed on the shore. Without running out to the truck and measuring clearance and then running a buncha calc's, what's the consensus?

(thanx for the bump, PFF)

|

|

|

|

|

Joined: Dec 2005

Posts: 668

Member

|

Member

Joined: Dec 2005

Posts: 668 |

Whoops, I was too late to stop the pour, but if it droops 5' in 52' that is much better than 72'!

Please no more rain for a month! :|

|

|

|

|

|

Joined: Feb 2005

Posts: 4,025 Likes: 1

Lunker

|

Lunker

Joined: Feb 2005

Posts: 4,025 Likes: 1 |

allowing 20' for boat and tongue, when the hitch is at 2ft of water, the motor will be in 4ft. I assume you want be getting a large boat, though. With the hitch at 1ft. the motor will be in 3ft.

|

|

|

|

|

Joined: Sep 2003

Posts: 13,750 Likes: 295

Moderator Ambassador Field Correspondent Hall of Fame 2014  Lunker

|

Moderator Ambassador Field Correspondent Hall of Fame 2014  Lunker

Joined: Sep 2003

Posts: 13,750 Likes: 295 |

Unless you are planning on water skiing, I would think you would find that some of the best pond boats to use are ones that one or two guys can move around or carry.

Burg, I'll front Brettski the $10 bucks to get a few dozen "verified" fatheads. Afterall, I'm anxious to get some fish onto Sunil's Mound and into Kopecky's Ditch.

Excerpt from Robert Crais' "The Monkey's Raincoat:"

"She took another microscopic bite of her sandwich, then pushed it away. Maybe she absorbed nutrients from her surroundings."

|

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |

Burgermeister peeks into the crystal ball... I assume you want be getting a large boat, though. - - ....yeah, nothing too much...it might look outta place on a pond. I'm kinda using this as my model:

|

|

|

|

|

Joined: Aug 2004

Posts: 8,854 Likes: 1

Moderator Ambassador Field Correspondent  Lunker

|

Moderator Ambassador Field Correspondent  Lunker

Joined: Aug 2004

Posts: 8,854 Likes: 1 |

Fabulous thread. Brettski, you're a new classification of Pondmesiter. You're more like a "Pondfreakster".  You really know how to do it up!

Holding a redear sunfish is like running with scissors.

|

|

|

|

|

Joined: Dec 2005

Posts: 668

Member

|

Member

Joined: Dec 2005

Posts: 668 |

Brettski- I don't see any help while you were pouring. Did you run the comealong and jitterbug by yourself? I am with Bruce, you are in a class all by yourself. "Pondfreakster Boss Supreme"

Please no more rain for a month! :|

|

|

|

|

|

Joined: Mar 2005

Posts: 957

Lunker

|

Lunker

Joined: Mar 2005

Posts: 957 |

Don't for get to install the "No Wake" bouys in front of the swim-up bar and position the ski jump to face into the prevailing wind.

You are truly a man with a passion.

Are you keeping a journal with all of this information and pictures? You have the makings for several articles in PB and a great reference for the rest of us.

1/4 & 3/4 acre ponds. A thousand miles from no where and there is no place I want to be...

Dwight Yoakam

|

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |

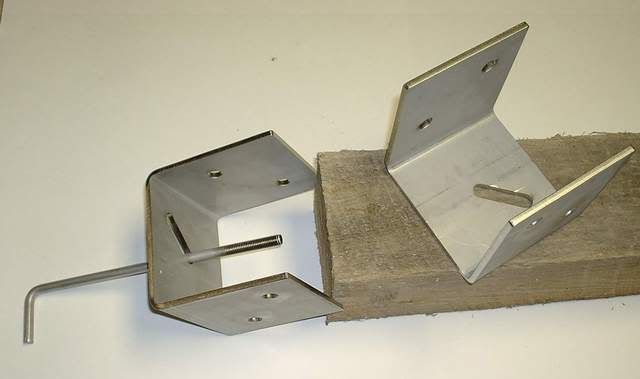

...OK, just a little bit on the concrete piers. We laid out the exact centers of each pier right on the ground and pounded a short pc of #3 rebar into dead-center. The real trick is to transfer this exact location vertically to the top of the poured concrete pier. Remember, the post-hole digger can have a mind of it's own, especially when it hits a substantial rock or root. Also, the hole is rarely perfectly plumb; this is usually the biggest offendor. I have used a measurement transfer method before with accurate success, but did not take pics of it's application during this project. I can expand on it and fudge in a pictorial should someone care to see it. OK, the holes are drilled, the tubes are FIRMLY placed within the holes, and the center locations have been transferred to the tops of the tubes. Time to pour concrete, right? Almost. Cut an extra tube, or a leftover cut-off, in half length-wise. It should be a min of about 24" or so. It will save a bunch of concrete over-spill.  - - As noted above, some of the drilled piers holes wound up with a slant. Instead of leaving the form tubes loose in the hole and propped up perfectly vertical with stakes and supports, I make sure they are tightly jammed in, won't move, and accept the lean. I used my eye to trowel down the surface to "close to level", then used a short bubble level (right on the wet concrete) to finish it. (you will also note that the anchor bolt is off-center. Not really...it is actually dead on WRT the layout)  - - We used 1/2" x 12" 18-8 Stainless Steel "L" anchor bolts. I left about 1" exposed to accommodate the post base, a couple of SS washers and a nut.  The 1/4" SS post bases will come into play a couple weeks out when we start framing.

|

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |

Well, another day in paradise...pass the Ibuprofen, please. When we brought through the concrete truck with 10 yards in the barrel 3 days ago, he found one soft spot in the new driveway constructed last Fall. Today, we summonned 14 tons of "oversize" (rock/clay), quasi-tailgated, adjusted with shovels (dozer and backhoe are long gone...ugh!), and mashed in with the tri-axle running back and forth. This one took about 2 hours of chain-gang misery. - - OK, now back to the subject...the launch. The forms popped off pretty darn easy. The smooth dowels worked out great. Finally, a project phase works as planned!  - - As noted in a previous post, we had some areas that deepened well below the 2 x 6 forms. We used additional 2 x 4's and and, in one area, additional 2 x 6's below the primary forms. Now I know where 9 yards of concrete went.  - - We re-used the forms and set 'em up for the next 31' of launch to be poured. We're gonna dowel this pour, also, because there will be one more pour to create an apron to tie back into grade.  - - Pursuant to some hyper-tension suffered a couple of days ago at the hands of PFF, I took specific elevation readings vs. length of launch run. At normal pool, we will have 56' of the launch underwater and the end will be at 5 ft depth. This, to me, is not ideal by any means but is acceptable for the application. No doubt, any truck will be in the water during a launch, but shouldn't be gurgling  . Sedans....this might be a problem.

|

|

|

|

|

Joined: Dec 2005

Posts: 668

Member

|

Member

Joined: Dec 2005

Posts: 668 |

Pursuant to some hyper-tension suffered a couple of days ago at the hands of PFF  I am glad I had a hand or hands involved in such a wonderful project. :rolleyes:  :p

Please no more rain for a month! :|

|

|

|

|

|

Joined: Sep 2003

Posts: 13,750 Likes: 295

Moderator Ambassador Field Correspondent Hall of Fame 2014  Lunker

|

Moderator Ambassador Field Correspondent Hall of Fame 2014  Lunker

Joined: Sep 2003

Posts: 13,750 Likes: 295 |

Those puddles are screaming "fatheads, fatheads, please!!!!" to me, and I can't get it out of my head.

Excerpt from Robert Crais' "The Monkey's Raincoat:"

"She took another microscopic bite of her sandwich, then pushed it away. Maybe she absorbed nutrients from her surroundings."

|

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |

...another sweaty day in paradise. Overcast and cloudy is a welcome blessing. We laid in the rebar for pour #2, tied the bars, and propped up the mat on bar chairs.  - - Continuous, multiple pours above grade are typically separated at the smooth-dowel seams with expansion joint. I conferred with a trusted friend and concrete contractor and he dismissed expansion joint as unnecessary for such a low-tech, underwater application. He did insist, though, on doweling the slabs together.  - - This is gonna be another pretty thick pour. Since I don't want to lose too much slope, as it is already lower than ideal, we are keeping the top end of the pour as high as practical. That, and the edges of this pour, like the first, drop off to create thicker edges. I'm guestimating 9 yards on this one.

|

|

|

|

|

Joined: May 2004

Posts: 13,974 Likes: 277

Moderator Lunker

|

Moderator Lunker

Joined: May 2004

Posts: 13,974 Likes: 277 |

On close examination, I don't see any backs on your rebar supports. They look more like bar stools than chairs.

"Live like you'll die tomorrow, but manage your grass like you'll live forever." -S. M. Stirling ![[Linked Image from i.pinimg.com]](https://i.pinimg.com/736x/ed/b5/e7/edb5e7f935843b996cf52be593c9ebd2--smoothie-smooth-collie.jpg)

|

|

|

|

|

Joined: Dec 2005

Posts: 668

Member

|

Member

Joined: Dec 2005

Posts: 668 |

In the future we will all try and call them "bar stools", so we can satisfy your aesthetic values! :rolleyes:

Please no more rain for a month! :|

|

|

|

|

|

Joined: Mar 2005

Posts: 821

Lunker

|

Lunker

Joined: Mar 2005

Posts: 821 |

Brettski,

I like your style! Great work and thanks for the photos.

gator

- Smoke 'em if you got 'em ![[Linked Image from i4.photobucket.com]](http://i4.photobucket.com/albums/y117/darnold01/Sheriff-Gator-Large.jpg)

|

|

|

|

|

Joined: Jul 2003

Posts: 214

Lunker

|

Lunker

Joined: Jul 2003

Posts: 214 |

Really nice work and very detailed. Thanks for sharing your project with us Brettski. I love to watch somebody that enjoys what they're doing.

CR

|

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |

We have elected to put the second slab pour on hold. Not only are we waiting for a series of rain-free days, but we need to re-charge the checking account. My in-house bookkeeper has been VERY cooperative in juggling the books to meet my all-consuming pondmeister's disease, but my suggestion to forego eating has been trumped. Somewhat distrought, I immediately hooked up the trailer and initiated a 2 hour therapy session at Menards. There's something magical about quality time spent selecting, pumping, and bench pressing a bunk of green treat lumber. More importantly, my green-treat health plan has been pre-approved and funded  . - The docks have been engineered to consider the lateral force of shifting ice as our strongest foe at the foundation. This is the reason rebar cages were embedded within the concrete piers. The stainless steel post bases (pic in prev post) should provide a stout transition from the concrete pier tops to the 6 x 6 green treat timber vertical supports. 2 x stock will be the connecting structurals. All this will be tied together with stainless steel hardware. After the concrete piers cured, and during our last visit to tie the rebar mat for the upcoming 2nd concrete launch pour, we shot the top elevations of each pier. This allowed me to run the calc's and pre-cut the cumbersome 6 x 6 verticals at home. The 2 x stock is much easier to handle and will be cut to size at the jobsite. The tops of the SS anchor bolts protrude about 1". I want the timbers to bear directly down and upon the supporting post base, so an accommodation hole must be bored. This was done with a 1.750" dia forstner bit on site. 1.750" dia was selected to elimate bearing restriction by the 1.500" dia double washers under the nut on the post base bracket. The accommodation hole was bored on site because it's location varied from pier-to-pier based on fine-tuning the post base bracket location within the overall layout. I had the brackets fabricated with a 2.5" long slot for just this very reason. After the hole is bored, we soaked the entire end of the timber and hole with preservative.  - - The vertical was dropped into the bracket and plumbed for level. 2 pc of 1/2" x 4" stainless lags are then cranked in, one from each side, to complete the vertical support. EDITOR'S NOTE: If you have ever done this kinda stuff and remember the time and effort expended spinning and cranking on a ratchet and socket to drive lag screws, there's a new sheriff in town. He's riding a compressor and slingin' an impact driver. Absolutely, positively, this is the only way to drive those beasts, hands down! (another editor's note: it just hit me like a ton'a'brix...DOH! I have a brand new Bosch hammer drill that I bought 2 years ago, sitting in a box in the basement. Betcha that would'a blown the bolt holes thru the timbers alot easier than the standard 1/2" drill I used. Like I said...DOH!) OK, I'm a little better now...let's continue. 2 x 8's were used as ledger boards. They are attached to the verts with 1/2" x 10" stainless carriage bolts (these are the holes that I was talkin' about during my above "hammer drill" epiphany). This foundation technique is typical and repeated for all the dock supports.  - - The dock at the this launch area has a 14' x 16' covered deck planned. This will be a construction headache unto itself and will be saved for another (soon to come) day. As a result, we are done for today on this dock after we install the 2 x 8 deck stringers. These outside stringer members are lagged into the verts with 5/16" x 4" stainless lags. The center stringer is toe-nailed into the ledgers with #10 x 3" stainless screws. 2 x 8 cross-blocking is planned between the stringers to minimize twist and rack; soon come. The resulting mass is strong. Donna-ski applies liberal coats of preservative to the tops of the verts as I chug Gatorade and take a few file pics.  - - We pack up the truck and head on over to the beach area (man, I can't wait for the day when that means a picnic and a dip in the water). Not today, lifeguard boy. Strap on your toolbelt, we got's mo' woik to du. We followed the exact same process at the beach dock, except this project is a somewhat simpler since there is no covered deck planned. The first section of dock is 20 feet long, parallel to the sand beach. The second "L" section is another 12', the last 2 feet cantilevered. We selected this spot to create the beach area because of it's southern exposure, topography, and great view. As planned, there is virtually no shade on the entire knoll. Enter another good decision; the 10' square collapseable shelter.  - - The "L" section was attached to the main dock section with stainless steel joist hangers. Instead of using nails, we opted for #10 x 3" screws to increase grip.  - - ...and then, the final product. This structure will also receive 2 x 8 cross blocks to resist twist and rack, but that will be the final touch before applying decking.  -

|

|

|

|

|

Joined: May 2004

Posts: 13,974 Likes: 277

Moderator Lunker

|

Moderator Lunker

Joined: May 2004

Posts: 13,974 Likes: 277 |

Good looking work, Brettski. I see the water's creeping a little closer to shore.

"Live like you'll die tomorrow, but manage your grass like you'll live forever." -S. M. Stirling ![[Linked Image from i.pinimg.com]](https://i.pinimg.com/736x/ed/b5/e7/edb5e7f935843b996cf52be593c9ebd2--smoothie-smooth-collie.jpg)

|

|

|

|

|

Joined: Apr 2006

Posts: 3,261

Ambassador Lunker

|

Ambassador Lunker

Joined: Apr 2006

Posts: 3,261 |

what kind of thought have you given deck material? since money is no object :rolleyes: i would recommend something requiring no maintenance other than sweeping, (i dont think you want to be re-applying stain or sealants in a couple years, over or near the water).

awesome project thread Brettski, you are truly making me dribble.....where's my bib?

GSF are people too!

|

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |

Ol' Dave is on the right track... what kind of thought have you given deck material? since money is no object i would recommend something requiring no maintenance other than sweeping, (i dont think you want to be re-applying stain or sealants in a couple years, over or near the water). The plan is definitely low/no maintenance. That, and a non-skid type surface. I haven't selected the decking yet, but the final choice must meet the aforementioned criteria. The plan here is to complete the framing for both docks, then "hit the hooks" to allow moving back to structure placement and other various periphery projects that I wanna address BW (before water). This way, I can keep my radar scanning for a good deal on decking. There is a popular auction held in the midwest for construction materials. One of my pals has attended and says that overruns and excess decking is a hi volume item...I gotta try to check out their Fall event. - - We shifted back to the launch zone and focused on the main deck at the end of the dock. This was the one I somewhat feared. You see, we buy pretty much all our lumber at Menards; good price, great selection and stock. I believe they own the pressure treating facility...? Anyway, they move so much of this stuff that the stock is always fresh outta the pressure treating vessel. I mean it weighs tons!  The main supports for this 14' x 16' deck is 4 pc of 6 x 6 timbers that vary in length between 10 and 12'. When we "selected" these weighty beasts from the rack at Menards, I knew a special "installation experience" was in my future. I brought ropes, straps, cleats, pusher boards, and about 5 engineering plans for not only elevating them onto the concrete piers, but holding them there while the connecting structures could be applied to keep them vertical. In the end, it was good old fashioned backbone and sinew that got them up there and couple of stakes with wood batter piles that held them plumb. WHEW, what a relief!  - - The main deck supports are 2 x 12 x 16', doubled up (one each side of the 6 x 6 vert) and thru-bolted with 3 pc 1/2" x 10" Stainless carriage bolts.  - - The floor joists are 2 x 10 x 14'. We flipped 'em up onto the deck supports to use as a temporary work deck. Next step, install the roof support members. A 2 x 10 cross member was installed to minimize racking and to tie the top of the verts. It also provides a shelf to set the main roof supports on for fastening to the verts (critical engineering foresight for a top-heavy and dangerously awkward construction segment). Identical to the deck support framing, 2 x 12 x 16' roof framing supports are installed.  - - After the opposing, second set of 2 x 12 roof framing supports are installed, that's it for the roof for this year. The Spring 2007 plan is to set pre-fab roof trusses at 24" OC attached with hurricane clips. 1 x battens and painted metal roofing will complete the roof structure (inspired by the Jeff Gaines project...thanks, Jeff. A note of thanks also goes out to Ahvatsa who spun off the Gaines design to another great dock/deck project)

|

|

|

|

|

Joined: May 2004

Posts: 13,974 Likes: 277

Moderator Lunker

|

Moderator Lunker

Joined: May 2004

Posts: 13,974 Likes: 277 |

Brettski, I have the reputation on both sides of the family for overbuilding projects. "Hell for stout," my late father-in-law often said.

Sir, that dock post-and-frame looks as well built as anything I have put together. My hat is tipped in recognition of your planning, execution, and documentary footage.

Forget going back to college. I hereby grant you an Honorary Doctorate from the Hardly Able School of Construction Engineering.

"Live like you'll die tomorrow, but manage your grass like you'll live forever." -S. M. Stirling ![[Linked Image from i.pinimg.com]](https://i.pinimg.com/736x/ed/b5/e7/edb5e7f935843b996cf52be593c9ebd2--smoothie-smooth-collie.jpg)

|

|

|

|

|

Joined: Jun 2003

Posts: 107

Lunker

|

Lunker

Joined: Jun 2003

Posts: 107 |

Brettski,

It is interesting to watch your progress - great pictures!

Make sure that you install some diagonal bracing to keep the structure square. My metal roof was a bit heavy and shaky until I added diagonals.

I am pleased to report that my dock has handled some intense storms. We got hit hard a month ago and I lost dozens of large oaks, hickory and ash, but the dock stood firm with no damage.

Jeff Gaines

|

|

|

|

|

Joined: Sep 2003

Posts: 13,750 Likes: 295

Moderator Ambassador Field Correspondent Hall of Fame 2014  Lunker

|

Moderator Ambassador Field Correspondent Hall of Fame 2014  Lunker

Joined: Sep 2003

Posts: 13,750 Likes: 295 |

It is quite impressive.

By the way, Brettski,....don't be too surprised if you see swarms of fathead minnows in those mini-ponds. I was there last weekend.

On a less desireable side note, 'Ole Mudcat Joe was there too, although he'll testify that he didn't stock any bullies.

Excerpt from Robert Crais' "The Monkey's Raincoat:"

"She took another microscopic bite of her sandwich, then pushed it away. Maybe she absorbed nutrients from her surroundings."

|

|

|

|

|

Joined: Nov 2005

Posts: 773 Likes: 1

Lunker

|

Lunker

Joined: Nov 2005

Posts: 773 Likes: 1 |

Brettski,

Holey Moley!!! You've done it again. You started another must read thread that I'll have to come back to several times a day to see if you've updated it.

Your dock sounds like it will be large enough to be very roomy and allow you to spend allot of time there with lots and lots of friends. In my next life, that's just what I want to do.

Thanks for sharing the pics and keeping us updated.

Eddie

|

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |

Professor Gallus delivers a coveted award for achievement: Forget going back to college. I hereby grant you an Honorary Doctorate from the Hardly Able School of Construction Engineering.

...this should help offset my high school graduating class vote of "most likely to party". - - Jeff, my trusted PB dock motivational speaker, offers sound engineering advice... Make sure that you install some diagonal bracing to keep the structure square. My metal roof was a bit heavy and shaky until I added diagonals.

I am pleased to report that my dock has handled some intense storms. We got hit hard a month ago and I lost dozens of large oaks, hickory and ash, but the dock stood firm with no damage.

I am glad that you mentioned this, Jeff. It was already on the drawing board, but I needed to hear it from "the man who owns one". You see, about 6 years ago I built an octagonal gazebo off our back deck, using very similar construction technique except the verts are 4 x 4. After attaching the roof, it was shaky and spindly...like a big, drunk spider in the wind. I added 4 x 4 diagonals, mitred and thru-bolted into an "X", between each vert. The spider sobered up, stout and tight as a drum, and went on to become the model for the War of the Worlds. :rolleyes: If you go back to my last post, where I describe attaching the double 2 x 12 x 16' support members to the tops of the verts, you will remember and see the 2 x 10 cross member that I installed just below them to tie the verts together and minimize some of the rack. The plan would be to add another 2 x 10 just the other side of the existing and thru-bolt the entire mass...just like the perpendicular 2 x 12's they support. Then, I can cut 6 x 6 diagonals about 3 or 4 feet long, mitre the ends at 45 degrees (like one section of a picture frame). They can be thru-bolted, sandwiched between the 2 x stock running horizontal, and the other end can be either lagged or thru-bolted to the 6 x 6 vert. It will be OTT for structural integrity, but look very cool. The drawback will be the head-room obstruction potential. I s'pose if one kept them closer to 3 ft long overall, the chance of head bumps is minimized. I truly mourn the loss of your beautiful trees. They are not so easily replaced... - - ...Sunil is relentless (and appreciated): By the way, Brettski,....don't be too surprised if you see swarms of fathead minnows in those mini-ponds. I was there last weekend.

How and where do I find "certified" fathead minnows? I have read enough on this forum to fear introduction of unwanted guests. (oh yeah, and for the record, Norm's Ditch has about 3-4" of water and Sunil's Mound stands another 2 feet higher, surrounded by water  ). - - Mr Walker chimes in support: Your dock sounds like it will be large enough to be very roomy and allow you to spend allot of time there with lots and lots of friends. In my next life, that's just what I want to do.

...Eddie, with your boundless DIY talent, I foresee you cutting down a redwood and carving the same deck, as one piece, with a stone sharpened grouser bar as a blade. Don't forget to wrap one end with a roll of ductape...I think that's how Henckels does it...? Oh yeah...and remember...all your hobbies have to wait 'til AFTER the dishes are cleaned and dried. No lip, Mister, or it's straight to the dozer without diesel!  - - (thanks, guys....your support means alot)

|

|

|

|

|

Joined: Jan 2005

Posts: 1,239

Lunker

|

Lunker

Joined: Jan 2005

Posts: 1,239 |

Brettski remember those house plans I sent you, in rereference you stated you were wanting to build a small retreat cabin. Looks to me like you are already well on your way with that monster dock, just add a few more piers and some walls and wa-la a cabin on the water. Then you can quite worring about the slopes to the house pad etc and you'll save a bundle too. Looks great like all the rest or your work thus far.

Eddie he's correct you'll have to schedule dozer time now.

The road goes on forever and the party nevers end...............................................

|

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |

...it seems the inventor in Rockytopper never takes a day off: ...just add a few more piers and some walls and wa-la a cabin on the water. C'mon RockyT...I promised the boss we would take a break after we finished framing it out. Besides, I'm thinkin a small houseboat might look nice tied up to it AND meet all the immediate camping requirements...once we see a bunch more water  . - - Well, 9 more yards of concrete and pad number 2 is poured and completed. This gives us 12' x 62' of launch. I figger the apron at the top will come in around 8 more ft of length.  We stole a couple of 5 gal buckets-worth of concrete out of the end of the pour to set the strainer support rod on the intake end of the dry hydrant line. I'll post pics on that with the balance of the dry hydrant installation pics. Oh yeah, and talk about a close guesstimate of required concrete. I wrestled with ordering what calc'd out to exactly 9 yards, or order 10 and not sweat it. Well, I went with 9 :rolleyes: . We had about 4 more feet of the pour to go to get to the top and the driver gets out and climbs up to look into the barrel...this can't be good. He shakes his head and says it's gonna be close. Well, we finish the slab pour (barely) and he swings the chute over to my 2 five gal buckets staged off to the side. We got exactly both of them filled by me using the shovel to scrape out the chute. Not another pebble more. Poifect...I used the buckets to fill the hole for the dry hydrant support rod; end of story!  - - A little lunch break, and back to the green treat. We put up the last 2 pc of 2 x 12 x 16' for the roof supports. Then we set the 2 x 10 x 14' floor joists by toe-nailing them into the 2 x 12 x 16' supports with #10 x 3" stainless screws. Then, we set blocks between the floor joists and screwed them thru the joists with the same screws. The resulting floor framework is solid.  - - OK, time to go back to the dock and tie the whole shootin' match together. We laid in the last 2 x 8 x 10' stringers. They span from the 3rd concrete dock support to the deck we just completed framing. The attachment to the deck is with the same size/type stainless steel joist hangers we used on the beach pier with the same type #10 x 3" stainless screws for fasteners. There will be a small step up from the dock to the deck...it was an engineering issue I had to accept...not a real biggie. Anyway, it came together well.  - - We'll see how the boss feels about spending her last day of vacation. She's probably thinking R & R and maybe dinner or lunch at a nice restaurant. I'm thinkin' "stackin' tire pyramids and settin' PVC trees". There must be a reasonable compromise....? - (edit; a day later, the reasonable compromise was a nice picnic at the pondsite AFTER wrestling with old truck/tractor tires and assembling PVC trees. I gotta think I got the better end of the deal :rolleyes: . For details, spin off to the PVC trees thread and head to the bottom of the page for installation.)

|

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |

Originally posted by Gainesjs:

Make sure that you install some diagonal bracing to keep the structure square. My metal roof was a bit heavy and shaky until I added diagonals.

I am pleased to report that my dock has handled some intense storms. We got hit hard a month ago and I lost dozens of large oaks, hickory and ash, but the dock stood firm with no damage. OK Jeff...done. I picked up 4 pc of green treat 6 x 6 x 8ft and pre-fab'd 'em at home. I cut each 8 footer dead center with a 45 degree cut. Then, I pre-drilled the 1/2" hole for the mounting bolt at each 45, adding a 1.500" dia countersunk hole to accept and recess the washer and nut. The other end of ea timber brace, the square end, is the easy one and will be drilled on site during installation. I picked up 16 more 1/2" x 10" SS carriage bolts and matching washers and nuts. Load up the generator and we're back off to the project. It took a couple of hours but turned out great.  - - Before we installed the diagonal timbers, I had to add one more 2 x 10 ledger opposite the existing ledger....cake. Then the top end of each diagonal (the square end)is sandwiched between the 2 x stock and thru-bolted with the 1/2" SS carriage bolts. The 45 degree cuts mated with the verts absolutely dead on and bolted on like they belonged there all along.  - - Now I have to keep my eyes and ears open to find a good deal on manufactured decking. After that, load up the trailer with pre-fab roof trusses and metal roofing. - QUESTION: I have very little exposure to metal roofing installation. I know that on a house a plywood or OSB roof deck should be installed. Should I do the same here or just use firring strips perpendicular to the trusses? I sure like the simplicity of firring strips AND the weight reduction.

|

|

|

|

|

Joined: May 2004

Posts: 13,974 Likes: 277

Moderator Lunker

|

Moderator Lunker

Joined: May 2004

Posts: 13,974 Likes: 277 |

Good work, Grasshopper. On metal roofing: Normal protocol is to use 2"x4"s (called purlins, today's $2 word that I didn't learn until my 4th barn), going perpendicularly across the trusses/rafter boards, to hold up the metal roofing, which itself is perpendicular to the purlins. Typical purlins spacing would be 2' apart, perhaps wider in areas with a lower expected snow load or for steeper roofs. The 2"x4"s are of course stronger in this role if oriented vertically (the 4" going up and down, the 2" contacting the rafters and the roofing). Concerned amateurs nail or screw the roofing through the raised ridges onto the purlins, barn #4's "professionals" (  :rolleyes: ) screwed it through the flats (we were a little unhappy about that - it may be OK since it's screwed, if nailed it would be a nightmare). Here's the best digital picture I could find of installed purlins and roofing (a ltttle blurry because the building was not the main subject). You can see the siding on the wall better and it is put on completely analogously to the roofing, other than the orientation of the 2"x4"s. I hop this helps.

"Live like you'll die tomorrow, but manage your grass like you'll live forever." -S. M. Stirling ![[Linked Image from i.pinimg.com]](https://i.pinimg.com/736x/ed/b5/e7/edb5e7f935843b996cf52be593c9ebd2--smoothie-smooth-collie.jpg)

|

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |

I want to go with 4/12 prefab roof trusses, 24" o/c. I have to imagine that 2 x 4 purlins at 24" o/c should be plenty stout. A 4/12 pitched metal roof should shed snow fairly well...? This being true, laying them flat should be reasonable practice...? Besides, what type/length of fastener would be used to go thru 3.5" of inverted 2 x 4, plus seat/bond with the support member?

|

|

|

|

|

Joined: Nov 2005

Posts: 773 Likes: 1

Lunker

|

Lunker

Joined: Nov 2005

Posts: 773 Likes: 1 |

Brettski, I have some experience with metal roofs on wooden buildings. The attached picture is of my wife as we put the roof on our home. The metal is attached to the purlins. It's always screwed on. NEVER nailed. The screws have rubber gaskets on them that you tighten until it starts to bulge. Too tight and you will break the seal. The screws go through the low part of the metal directly into the purlins. You NEVER attach a metal roof through the ridges. Metal comes in three foot widths, but it's easy to overlap sections in one foot widths. Your supplier will pre-cut it to you in any length you want. Spacing of your truss's can vary from four feet to 16 feet or more. I like 4 foot centers on my truss's. Your purlins need to span the width of each truss. I like 12 foot pulins and I stagger there ends. Each one up starts on a different truss to tie everything together. My purlins are on 4 foot centers. Without snow, you can put them further, but snow load and pitch need to be engineered if you do that. I wouldn't. You can put them closer if you like, it's just extra lumber. With your truss's on 4 ft centers, you can use 2x4's on there flat sides. Further spacing of the trusses will require 2x4's on there edges. It's real easy to attach them on there flats, so that's the way I do it. This also gives you a large surface to attach your metal panels. I buy my stuff at www.muellerinc.com here in Texas. I know they are not in your area, but they have a good website with prices that should give you some ideas. Home Depot and Lowes don't sell good metal. If you want to do it once, buy from a metal building supply house. The main failure point on metal roofs is the screws. Mostly it's from overtightenign them, but cheap screws will fail. They either have inferior rubber gaskets or the metal is crap. Buy quality screws!!! To keep it simple, build a gable roof. A hip roof might look nicer, but it's more work and the framining is allot more involved. Have fun, Eddie

|

|

|

|

|

Joined: May 2004

Posts: 13,974 Likes: 277

Moderator Lunker

|

Moderator Lunker

Joined: May 2004

Posts: 13,974 Likes: 277 |

If the 2"x4"s are attached upright, you put two nails in at an angle from opposite sides. They only go through the bottom 1/2 to 1/3 of the purlin.

The barn pictured above has purlins every (IIRC) 28" or so, with a 5 foot span between the trusses (center section) or rafters (side sections). Given your purlins will only have to span 2' between trusses, laying them flat should be no problem at all.

I think 4/12 pitch trusses should be fine for your snow load, even if you're in the Lake Michigan snow belt, unless you're putting on gutters. A steel roof sheds snow a lot easier than shingles. 4/12 is not too bad to work on after it ages; roof sheets IME are shipped dripping with a silicon spray-like preservative that is really slippery until it drips/weathers off (it tastes lousy, too). Even if there's no preservative to speak of, they roughen up a little after the galvanized starts to oxidize. The roof above I worked from a roofing ladder suspending by rope from the opposite side of the barn, passed over the crown. But it has a lot bigger span and a lot higher drop (20+' for the center section) than your dock.

Use screws to hold the sheeting down. I used to make good money renailing steel roofs on pole barns after they'd aged a few years.

Are you going to seal off the under side of the trusses with sheeting like the classier dock roofs we've seen pictured here? It'd be nice to have it bird-, bug-, and varmint-proofed. Although the challenge of shooting a raccoon out of ones trusses without holing the roof can be fun.

"Live like you'll die tomorrow, but manage your grass like you'll live forever." -S. M. Stirling ![[Linked Image from i.pinimg.com]](https://i.pinimg.com/736x/ed/b5/e7/edb5e7f935843b996cf52be593c9ebd2--smoothie-smooth-collie.jpg)

|

|

|

|

|

Joined: Jan 2005

Posts: 1,239

Lunker

|

Lunker

Joined: Jan 2005

Posts: 1,239 |

Just to clarify what Eddie stated qoute " You NEVER attach a metal roof through the ridges."

His statements are true, however they do make lap joint screws that are designed to be screwed thru the ridges to connect each sheet to each other. They also make a seal tape that is applied between the sheets under this ridge joint. For steeper roofs like 6-12 pitch the seal is not really necessary but it is recomended for flatter slopes like 2-12.

The road goes on forever and the party nevers end...............................................

|

|

|

|

|

Joined: Nov 2005

Posts: 773 Likes: 1

Lunker

|

Lunker

Joined: Nov 2005

Posts: 773 Likes: 1 |

Rockytopper,

Thanks. There are two different types of screws. One that will drill through the metal and fasten to wood and anthere that is for metal to metal.

Eddie

|

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |

...Theo means well, but somehow it turns into more work and expense: Are you going to seal off the under side of the trusses with sheeting like the classier dock roofs we've seen pictured here? It'd be nice to have it bird-, bug-, and varmint-proofed. I considered it, but nothing more than a passing thought. Give me some ideas on SOP.

|

|

|

|

|

Joined: Mar 2005

Posts: 21,499 Likes: 267

Moderator Hall of Fame 2014  Lunker

|

Moderator Hall of Fame 2014  Lunker

Joined: Mar 2005

Posts: 21,499 Likes: 267 |

Be sure to look into the quality of the screws and rubber gaskets. One of my partners has a country house about 8 years old with a metal roof (life time guaranty on the roof but not the screws). The roof is in great shape but he found a leak. When he got it checked he found out that the gaskets have all deteriorated and every one must be replaced.

|

|

|

|

|

Joined: May 2004

Posts: 13,974 Likes: 277

Moderator Lunker

|

Moderator Lunker

Joined: May 2004

Posts: 13,974 Likes: 277 |

Originally posted by Brettski: ...Theo means well, but somehow it turns into more work and expense:

Are you going to seal off the under side of the trusses with sheeting like the classier dock roofs we've seen pictured here? It'd be nice to have it bird-, bug-, and varmint-proofed. I haven't done it myself, Bski, but I believe there have been 2 or 3 nice docks pictured here with the bottom of the trusses covered. The walkway from the house to the garage/apartment at Lusk Lodge II is done this way - pics in one of the last 2 issues of PB Mag.

"Live like you'll die tomorrow, but manage your grass like you'll live forever." -S. M. Stirling ![[Linked Image from i.pinimg.com]](https://i.pinimg.com/736x/ed/b5/e7/edb5e7f935843b996cf52be593c9ebd2--smoothie-smooth-collie.jpg)

|

|

|

|

|

Joined: Jan 2005

Posts: 1,239

Lunker

|

Lunker

Joined: Jan 2005

Posts: 1,239 |

Brettski it is also a good idea to pre drill the sheets with a hole bigger than the screw dia but still small enough to be sealed by the washer. The reason is to allow the sheets room to expand and contract with temperature changes.

The road goes on forever and the party nevers end...............................................

|

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |

So, I’m in the midst of planning completion of the launch dock/deck and the dock at the beach area. The launch dock/deck will require decking, roof trusses with purlins, and the metal roofing. The beach dock is considerably simpler, requiring only decking. The next step for both is obvious; installing the decking. I have installed numerous square feet of decks in my lifetime. All of it has been treated lumber, both the frame and the decking. Whenever I completed a deck, I would always admire its beauty. About 2 or 3 years later, I would swear that next deck would be a composite type decking to eliminate maintenance and prolong aesthetic appeal. I haven’t forgotten this self-imposed promise for these upcoming projects. I still firmly believe in treated lumber for the framing, but I have strongly voiced my belief to spend the money for a better decking product. Well, here I am….it’s time to pull the trigger. I have been doing my due diligence on decking material and, as usual, now know enough to be dangerous. The way I see it, there are three basic material compositions to consider. A) Treated lumber B) composite decking C) Hi density polyethylene (HDPE). The treated lumber is easy to understand since it is the most commonly used product for these type structures. The composite decking is a bit more complicated because it is a blend of plastics and wood fibre. There are different blends and percentages of content. They do eventually break down, mostly because of the wood fibre content. The warranties vary, mostly from 10 – 25 years. The price corresponds. Then I researched HDPE. I was sure I found my new hero. It is a 100% solid plastic product, UV protected, and the warranties are in the 50-year range. They mold the stuff with the color throughout the plastic, so any scratches or gouges reveal the exact same color. Also, the finish is molded with faux wood grains for “looks” and traction. I will admit that, based on on-line product pics, the close-up aesthetic appeal is, well, plasticky. But this is a boat dock. Sure, I want it to look good, but more importantly I want it to wear and last forever….zip maintenance. I think this stuff gets me there. No matter what product I select, I definitely plan to use hidden fasteners. I did a very small stair-step project last year and tried the under deck galvanized rails. These are the 4‘ long continuous strips that you screw to the top edge of the framing joists. They have pre-punched holes every 1” that will accommodate a deck screw that is run upward and into the bottom of the decking board above it, drawing it down to the galvanized strip and (theoretically) snug against the framing joist. It is awkward work and I was not impressed with the results. I am sold (until further notice) on the Eb Ty hidden fastener system. This is the plan for fastening whatever I finally do select. So, I am now searching and hoping to find an HDPE product that I can afford. This is my first forbidding barrier. All the name brands that are true HDPE are mega-expensive. The only one I found locally to inspect was an extruded product that looked really great on a display at one of the local lumberyards. It’s called Eco. A piece that is 5.5” wide x 16’ long costs $41. Yikes! Then I found what I hoped to be my answer to the HDPE affordability equation. A factory that actually makes the stuff and will sell retail direct. EPS Plastic Lumber . They have a plant in the Chicago area…perfect! This stuff is absolutely killer. A true 2 x 6 (1.5” x 5.5”) dimensional lumber…err…plastic. They have some closeout product that will work perfectly for my launch dock/deck; the 16’ pc is $38 each. And this is a good deal…? Here’s how I calculate this. I am going to focus only on the launch dock/deck for completion (the beach dock is far away from the living zone of the pondsite, so it is not as important for looks….the launch area is). Anyway, to deck the entire launch dock/deck with this HDPE deal that I found, it will cost $2200 in materials and hidden fasteners. I think Curly Howard said it best: Nyaah, aah, aah! Now, for the flip side, to do the same area in 2 x 6 treated lumber for the decking, including Eb Ty hidden fasteners, the total cost would be $700. Another factor: the plastic lumber will weigh 1100# for just the 14’ x 16’ deck. That’s a lot of weight, ain’t it? Oh yeah, and get this. Dski is with me and has approved funding of the big bux product if I am 100% sure of the quality and longevity. I really only have one big problem: I can’t do it. I can’t bring myself to spend that kind of dough for this project. So, I analyze it the best I can and this is where I wind up. If I use the Eb Ty hidden fasteners and do a nice job of securing the treated 2 x 6 decking, it will last forever (or at least my lifetime). Accept the fact that it will weather and turn a dull gray and many of the boards with split and crack here and there. At least there won’t be that snappy look of a gazillion screw-head craters. With the money left over (2200 – 700 = $1500), buy the roof materials and finish it off for the same amount of dough as just the plastic magic-deck. Heck, if I do the beach dock with treated, I might be able to use the savings to buy a power washer for lazy cleaning maintenance and a couple gallons of good transparent stain to fake myself out. ….or, do you pull the trigger and buy the killer plastic lumber? - - (a nice product summary by This Old House)

|

|

|

|

|

Joined: Mar 2004

Posts: 229

Lunker

|

Lunker

Joined: Mar 2004

Posts: 229 |

Of all your living areas how much time will you spend at the dock/deck?

Where will be the first place you take guests?

We don't live on our pond, the dock is crude, yet it is the center of action in the summer. And after we build a house I would guess the dock will still be the center of a lot of action.

Of course when the treated lumber decking fades, if it doesn't bother you, I would bet it wouldn't bother anyone else.

Faded wood might even be a good look around the pond.

|

|

|

|

|

Joined: Nov 2005

Posts: 773 Likes: 1

Lunker

|

Lunker

Joined: Nov 2005

Posts: 773 Likes: 1 |

I've had just a little bit of exposure to the new decking materials and haven't seen one yet that I like over PT Wood. In addition to there upfront price, you really need to have your joists on 12 inch centers. Even then, some will begin to sag over the years.

I screw down the decking on my projects. I like to snap a chalk line to get them all lined up too. Then I screw them down until the heads disapear into the wood. Two screws per joist for the length of the board.

If you do go with PT wood decking, buy it a month or two before you install it. The shrinkage in that first few weeks will be severe. Then it will stabalize and you can get your spacings pretty accurate.

Don't spread them out, just stack them outside so they will keep from warping while drying out. Home Depot and Lowes will take warped ones back, so don't mess around with any of them. No point in it. I ususally buy a dozen extra with the plans to return what's not used.

I like the look of weathered wood, but Thompsons has there water seals in colors now. You just spray it on every year and it looks great.

Eddie

|

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |

Home Depot and Lowes will take warped ones back, so don't mess around with any of them. ...ever use this thing? If you're unsure, read the reviews on Amazon. I just ordered my Bowrench .

|

|

|

|

|

Joined: Jan 2005

Posts: 469

Lunker

|

Lunker

Joined: Jan 2005

Posts: 469 |

Brettski, If you hadn't signed your post, I would have thought I wrote it myself. I was not even going to consider PT wood for my dock, until I saw the price. It's 4X the price! So I am going to use PT as well. There is a wood protection product sold at Sherwin Williams called Deckscapes. It has been highly recommended to me by several painters. It is water based, and it's not cheap, but the money saved not buying plastic justifies the cost, especially if it is as good as I have heard. Look HERE

Hey Moe, I'm trying to think but nuthin's happening!

|

|

|

|

|

Joined: May 2004

Posts: 13,974 Likes: 277

Moderator Lunker

|

Moderator Lunker

Joined: May 2004

Posts: 13,974 Likes: 277 |

After 17 years, we are finally figuring on putting the deck on the back of our house this year. Currently we are contemplating using TimberTech , which is a wood-fiber-and-plastic composite. IIRC SOP is to install this material as decking over a regular treated lumber frame. One of their alleged benefits we are after is the ability to water-proof (and bug-proof) the top deck of a two-story structure. The owner of the local lumber yard carrying the stuff is one of the neighbors that we actually get along with (lumber yard owners seem less upset by logging) and we will have to go next door and check out the Timber Tech deck on his house - it's been up a few years now. Their "Docksider" planks are designed for 24" center-to-center supports.

"Live like you'll die tomorrow, but manage your grass like you'll live forever." -S. M. Stirling ![[Linked Image from i.pinimg.com]](https://i.pinimg.com/736x/ed/b5/e7/edb5e7f935843b996cf52be593c9ebd2--smoothie-smooth-collie.jpg)

|

|

|

|

|

Joined: May 2004

Posts: 234

Lunker

|

Lunker

Joined: May 2004

Posts: 234 |

" The owner of the local lumber yard carrying the stuff is one of the neighbors that we actually get along with (lumber yard owners seem less upset by logging)" Theo, Do your other neighbors use plastic toilet paper?  I personally support sound logging practices of a renewable and sustainable resource. Ed

|

|

|

|

|

Joined: May 2004

Posts: 13,974 Likes: 277

Moderator Lunker

|

Moderator Lunker

Joined: May 2004

Posts: 13,974 Likes: 277 |

They probably use a bidet. ("It's for washing off your backside!") Ed, we had a couple of them complain that when they bought their property, there were woods next door, and then we had them logged.  We replied that when we bought our place, there was another farm next door, then they put in a subdivision. :p

"Live like you'll die tomorrow, but manage your grass like you'll live forever." -S. M. Stirling ![[Linked Image from i.pinimg.com]](https://i.pinimg.com/736x/ed/b5/e7/edb5e7f935843b996cf52be593c9ebd2--smoothie-smooth-collie.jpg)

|

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |

DONE DEAL  Green treated 2 x 6 x 8' and 16'. I'll plan for installation over Memorial Day...I hope. That'll give 'em some time to dry out a bit. In the meantime, they will stay packed up tight to see if that helps to alleviate twist and bow while they cure.

|

|

|

|

|

Joined: Sep 2003

Posts: 13,750 Likes: 295

Moderator Ambassador Field Correspondent Hall of Fame 2014  Lunker

|

Moderator Ambassador Field Correspondent Hall of Fame 2014  Lunker

Joined: Sep 2003

Posts: 13,750 Likes: 295 |

Memorial Day??? That's like over two months away.

Brettski, please try and bear down to get your project done. No need to idle around wasting time.

Excerpt from Robert Crais' "The Monkey's Raincoat:"

"She took another microscopic bite of her sandwich, then pushed it away. Maybe she absorbed nutrients from her surroundings."

|

|

|

|

|

Joined: Mar 2005

Posts: 957

Lunker

|

Lunker

Joined: Mar 2005

Posts: 957 |

Classic Sunil, just classic.

1/4 & 3/4 acre ponds. A thousand miles from no where and there is no place I want to be...

Dwight Yoakam

|

|

|

|

|

Joined: Nov 2005

Posts: 773 Likes: 1

Lunker

|

Lunker

Joined: Nov 2005

Posts: 773 Likes: 1 |

At first glance, I thought the stack of wood had been delivered by a fork lift as it came off the truck. Then I noticed that you have it stacked with spacers between the boards to allow air circulation. Very nicely done!!!

I bet you got yourself a nice workout moving all the lumber around!!! And in a few months you get to load it up and move it again!!!!!

Keep us updated as I'm really interested in the results of your air drying/stacking method.

Thanks,

Eddie

|

|

|

|

|

Joined: May 2004

Posts: 13,974 Likes: 277

Moderator Lunker

|

Moderator Lunker

Joined: May 2004

Posts: 13,974 Likes: 277 |

Nothing says Love like Lumber. Keeping it strapped together should help cut down on warping.

I thought it was "as delivered" too, Eddie - I had to go back to see the shipping bands had been replaced with nylon strapping.

"Live like you'll die tomorrow, but manage your grass like you'll live forever." -S. M. Stirling ![[Linked Image from i.pinimg.com]](https://i.pinimg.com/736x/ed/b5/e7/edb5e7f935843b996cf52be593c9ebd2--smoothie-smooth-collie.jpg)

|

|

|

|

|

Joined: Apr 2003

Posts: 823

Lunker

|

Lunker

Joined: Apr 2003

Posts: 823 |

Theo:

I installed TimberTech (tongue and groove version) on our front porch 5 years. It was WAY expensive and terribly heavy...however, it was one of the best decisions I made in our remodel project. I'm kind of a slob and tend to track lots of "stuff" around. Spring and fall...2 gallons of bleach in a hand sprayer, soak it well, wait 20 minutes or so and hose it off. VOILA...brand new looking, all over again. It's also absolutely arrow straight, and stays that way.

It does fade, to a very light gray/brown color, but it works incredibly for us. ABSOLUTELY no sag, give or anything on 16" treated 2x8 joists. I also considered it on my floating dock, but the price and weight were a bit much.

BTW..for anyone considering using EBTys on treated 2x6 decking, better reconsider. Without a fastener in the middle, the boards will tend to warp upwards (cup) in the middle. I'd at least use one (SS) screw in the middle of each board at each joist. Been doing construction long enough to know that this will be necessary.

In a lifetime, the average driver will honk 15,250 times. My wife figures I'm due to die any day now...

|

|

|

|

|

Joined: May 2004

Posts: 13,974 Likes: 277

Moderator Lunker

|

Moderator Lunker

Joined: May 2004

Posts: 13,974 Likes: 277 |

Originally posted by Matt Clark:

It does fade, to a very light gray/brown color, but it works incredibly for us. What color did you install?

"Live like you'll die tomorrow, but manage your grass like you'll live forever." -S. M. Stirling ![[Linked Image from i.pinimg.com]](https://i.pinimg.com/736x/ed/b5/e7/edb5e7f935843b996cf52be593c9ebd2--smoothie-smooth-collie.jpg)

|

|

|

|

|

Joined: Apr 2003

Posts: 823

Lunker

|

Lunker

Joined: Apr 2003

Posts: 823 |

Theo...5 years ago, it was only available in 1 color, a light brown/tan. Maybe it's in more colors now, but as it's plastic, it WILL fade, regardles of what they tell you. Eventually, most any color (other than pure white, as titanium dioxide negates nearly all UV light fading) will end up it's natural shade of light gray, nearly white.

I can take some photos if you'd like to see what it looks like now, 5 (hard) years down the road...

In a lifetime, the average driver will honk 15,250 times. My wife figures I'm due to die any day now...

|

|

|

|

|

Joined: May 2004

Posts: 13,974 Likes: 277

Moderator Lunker

|

Moderator Lunker

Joined: May 2004

Posts: 13,974 Likes: 277 |

IIRC it comes in red, brown or grey now. I'm hoping for low maintenance, as I hate fixing anything except dinner for fish and fish for dinner.

"Live like you'll die tomorrow, but manage your grass like you'll live forever." -S. M. Stirling ![[Linked Image from i.pinimg.com]](https://i.pinimg.com/736x/ed/b5/e7/edb5e7f935843b996cf52be593c9ebd2--smoothie-smooth-collie.jpg)

|

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |

4-07 Update We are well into spring and the pond is quickly creeping up the shoreline as it stretches for the spillway pipe. My laundry list of improvements for the project is still long and alot of the jobs need to be completed before the water arrives. This includes the last pour of the launch. We are thankful that this one is small compared to the other two 31' long pours. This slab is only 8 ft long x the 12 ft width.  - - We just unloaded the fish delivery and moved right into tying rebar.  This last pour will require barely 2 yards. The concrete company del's 3 yards min for no dely charge. Less than that, add $75 dely. Heck, a yard costs 80 some odd bux. I gotta come up with another use for another yard of concrete....or more. Is it time to start the 16' x 24' shed???

|

|

|

|

|

Joined: Apr 2003

Posts: 823

Lunker

|

Lunker

Joined: Apr 2003

Posts: 823 |

Yeak Brettski, you gotta find someplace to pour that last yard...can't pay something for nothing. I've even laid out ladder-type forms and just poured blocks to toss in the pond for structure...but a yard would make a helluva lot of them... Any place you might want to set a bench or something out there, in the future?

In a lifetime, the average driver will honk 15,250 times. My wife figures I'm due to die any day now...

|

|

|

|

|

Joined: May 2004

Posts: 13,974 Likes: 277

Moderator Lunker

|

Moderator Lunker

Joined: May 2004

Posts: 13,974 Likes: 277 |

You could always put in a sidewalk to where the dock begins.

"Live like you'll die tomorrow, but manage your grass like you'll live forever." -S. M. Stirling ![[Linked Image from i.pinimg.com]](https://i.pinimg.com/736x/ed/b5/e7/edb5e7f935843b996cf52be593c9ebd2--smoothie-smooth-collie.jpg)

|

|

|

|

|

Joined: Apr 2003

Posts: 823

Lunker

|

Lunker

Joined: Apr 2003

Posts: 823 |

Right now, I'm considering putting a "sidewalk" sort of pad down near the bridge. Got several older folks that love to fish, but can't stand for long. Even though the slope seems relative minor to me (maybe 5:1) it's hard for Al to sit in a lawn chair there...42"x10 foot pad would be ideal for him and wifey's gramma...we drive right to it, anyway, and it's be nice for them.

Just another thougt...

In a lifetime, the average driver will honk 15,250 times. My wife figures I'm due to die any day now...

|

|

|

|

|

Joined: May 2004

Posts: 13,974 Likes: 277

Moderator Lunker

|

Moderator Lunker

Joined: May 2004

Posts: 13,974 Likes: 277 |

A good thought, Matt. Flat, no erosion spots for lawn chairs can seem like a God send.

"Live like you'll die tomorrow, but manage your grass like you'll live forever." -S. M. Stirling ![[Linked Image from i.pinimg.com]](https://i.pinimg.com/736x/ed/b5/e7/edb5e7f935843b996cf52be593c9ebd2--smoothie-smooth-collie.jpg)

|

|

|

|

|

Joined: Apr 2003

Posts: 823

Lunker

|

Lunker

Joined: Apr 2003

Posts: 823 |

It never really crossed my mind until this past Saturday...older folks deserve the absolute best. Al and Geneva have earned it, along with others who may show up over time.

In a lifetime, the average driver will honk 15,250 times. My wife figures I'm due to die any day now...

|

|

|

|

|

Joined: Jan 2006

Posts: 16,055 Likes: 277

Moderator Lunker

|

Moderator Lunker

Joined: Jan 2006

Posts: 16,055 Likes: 277 |

I like Theos idea. Old folks really don't like muddy walkways to the dock.

It's not about the fish. It's about the pond. Take care of the pond and the fish will be fine. PB subscriber since before it was in color.

Without a sense of urgency, Nothing ever gets done.

Boy, if I say "sic em", you'd better look for something to bite. Sam Shelley Rancher and Farmer Muleshoe Texas 1892-1985 RIP

|

|

|

|

|

Joined: Nov 2005

Posts: 773 Likes: 1

Lunker

|

Lunker

Joined: Nov 2005

Posts: 773 Likes: 1 |

Brettski,

Anything new with the boathouse? I remember you bought a load of lumber, and I'm trying to be patient, but it must be nice weather there now!!!

Eddie

|

|

|

|

|

Joined: Oct 2005

Posts: 6,934 Likes: 2

Ambassador

Field Correspondent Lunker

|

OP

Ambassador

Field Correspondent Lunker

Joined: Oct 2005

Posts: 6,934 Likes: 2 |