6 foot of water requires 2.6 psi from the pump (6 foot X 0.433 psi/foot = 2.6 psi).

A range I use for fittings and valves overall would be .5 to 1 psi. We'll use 0.75 psi. This assumes fittings and valves that do not get smaller than the pump outlet and are closer to the line inner diameter everywhere possible.

Diaphragm diffusers vary with respect to how much pressure they take to operate, but we'll use a 0.5 psi requirement that should be close.

We must guess a bit on the line length pressure loss to get started. Let's use the 1 psi estimate for the 3/4" line from earlier.

Add all those up and you get… 2.6 + 0.75 + 0.5 + 1 = 4.85 psi. Looking at your curve to get the CFM at the 4.85 psi (the green line is for 60 Hz IIRC)...

At this estimate, your pump would be putting out about 5.2 CFM. Start at where 4.85 would be on the bottom scale, go straight up until you hit the green curve, then cut over to the right until you hit the “CFM” scale. That should hit around the 5.2 CFM mark. This is a good place to be with respect to air flow for 4 diffusers. IIRC, Matala's are factory rated around 1.5 CFM per head and good rumor has it that they handle 2 CFM nicely, but also operate well at 1 CFM.

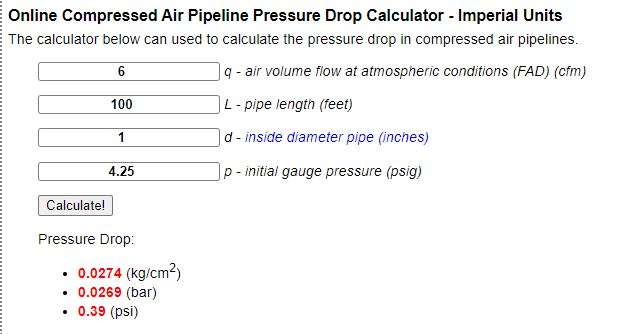

Running a pressure loss calculator located here…

https://www.engineeringtoolbox.com/pressure-drop-compressed-air-pipes-d_852.html![[Linked Image]](https://forums.pondboss.com/ubbthreads.php?ubb=download&Number=18218&filename=HB200 0.75 line.JPG)

This shows that our first take on the pressure-loss-guess (1 psi) is very close to theoretical reality (1.1 psi– dang close, we got lucky).

According to these estimates, Id’ say ¾” line would operate the difusers well assuming that your pond can be turned with the 4 heads at 5.2 CFM.

BUT, it would be operating beyond the Max Continuous Operating Pressure that you stated in your original post of 4.3 psi. Going by the book…the manufacturer does not recommend this scenario. Only real-life experience would convince me to run it this way otherwise.

Let’s run the 1” line to see the difference in performance. Changing the line diameter from above, only, in the linked calculator is not the only step because by making the line size larger causes the pressure to lessen which changes the CFM’s that the pump can put out which are both entries for the calculator…So, It may take some iterations to get the calculator to closely match the pump curve.

After a few tries we get very close…

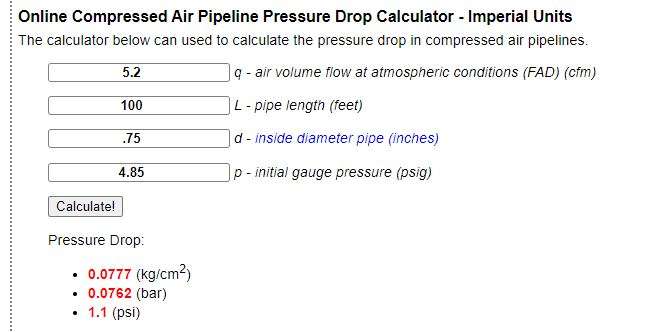

At first, I assumed a pressure loss (or drop) from the 1” hose to be 0.2 psi and added it to the pressure from water depth (2.6), fitting and valve restriction loss (0.75), and diffuser requirement (0.5), used the pressure total and the correlating CFM from the chart, but did not get the calculators pressure loss to match the 0.2. I kept bumping the pressure loss from the 1” line up, using the new correlating CFM from the chart until the assumed pressure loss matched the calculator’s pressure loss result. I ended up here…

2.6 + 0.75 + 0.5 + 0.4 (new 1” pressure loss) = 4.25 psi

![[Linked Image]](https://forums.pondboss.com/ubbthreads.php?ubb=download&Number=18217&filename=HB200 1.0 line.JPG)

4.25 psi correlates with 6 CFM from the pump curve. With these numbers and 100 foot of 1”, the calculator figured a number very close to our 0.4 psi guess. I stopped here to conclude that the 1” line would allow the system to produce the 6 CFM with 1’ line over the 5.2 CFM with the ¾” line. Not a huge increase, but substantial…AND it gets the pump working closer to the ideal point on the curve (the orange line recommended by the manufacturer) AND away from the Max Continuous Operating Pressure, barely. 1” line gets you about 15% more air flow to the diffusers and does not work the pump as hard. Either line size (3/4” or 1”) should operate the diffusers in a good fashion, but the 1” will yield some improvements over the ¾” by getting the pump to a lower operating pressure.

Keep in mind that the above mumbo-jumbo made some assumptions regarding fitting & valve restriction losses and diffuser pressure requirements. If these assumption are generally too high, then the system would be in a better operating range. The opposite is the case if the assumptions are low. Only true testing can prove one way or another...Do you have a pressure gage on your pump outlet?

All in all, you would be very close to the line of good operations, but it’s very difficult to say which side of the line you would be on. The CFM would be appropriate for the heads, could be better, but at a good place. The worry would be, being so close or above the Max Continuous Operating Pressure.

EDIT: I would recommend using the 1" line and reducing it's overall length to 75', maybe even 50 if you can convince yourself to move the diffuser that far in. 75 foot long would take about 0.1 psi of pressure off the pump compared to 100. 50' would take about 0.2 psi of pressure off the pump compared to 100.

![[Linked Image from i.ibb.co]](https://i.ibb.co/KwKdrkr/FAD446-FF-3887-49-B7-8-D88-41534-E545-CD1.jpg)