3/4 acre pond with average 8 ft deep and 12 ft max I think I’ve got a good game plan down but would like confirmation because these set ups aren’t cheap.

So from what I’ve gathered reading thru old posts it seems the gast 0523 is the way to go for me. I plan on running a diffuser to deep part as well as to shallower 6 ft part on other side of pond. From the pump I will have a manifold going to 2 valves and then gauges to read the pressure. I’ll use weighted 3/4 air hose to run 100ft to deep end and 60 ft to shallow part.

Should I run a double diffuser for deep end or will a vertex 9” work? I already purchased a 12” matala head that I need to rig up to weights and what not but I can return that for something better. Do I need anything else in the manifold area?

Also what’s everyone using to house the compressor? I saw some polycarbonate cabinets with fans for sale but they are still over 200 bucks.

You could use that 12" one in the shallow area for winter to keep an area ice free (if your pond freezes over in the winter) and use most likely 2 of the Vertex ones in the deepest part. Check their lifting rates and calculate the total gallons in your pond. See if one will turn your pond in the length of time you want to run your compressor during the summer for each day. If one will lift the number of gallons you need to bring to the surface, you only need one. If not, then you have to use two.

You only need 1 gauge, but you will also need a pop-off valve so you don't over pressure the system is something blocks the airline. You don't want to stall out the compressor and burn it out.

As for a cabinet, anything that will house the compressor and will also hold a fan to suck air into the cabinet to keep the compressor relatively cool. You will need a "larger than furnished with the compressor" intake air filter too.

If I remember I will take a picture of what we did at a customers place for them tomorrow. There is no compressor cabinet because the compressor is inside a large shed.

Thanks for advice. I guess if I were to run them both at same time I would need separate gauges? And if I were to get the double for the deep part I doubt I would need them both run. The pond is somewhat oval shape so the deep part is more towards one end of the oval.

Also you think I can get away with 1/2 lines? Not seeing many options for 3/4 on basic search.

You only need one gauge for the whole system, not for each diffuser. The 1/2" ID lines will work, typically the self sink lines are between 1/2" and 5/8" ID. You can put the gauge on the manifold at the edge of the pond, or if you have a manifold near the compressor you can put it there. Same with the single pop-off valve, it can be mounted anywhere. I'd get one that opens between 15 psi to 25 psi maximum.

Awesome thanks. And from what I’m reading the XL1 should be more than sufficient to turn the water over if ran constantly. I’m at about 2 million gallons and it will do almost 3. However if I get the double I could probably run the pump half the time thus saving energy and pump life. Will just cost a bit more up front.

It will be less expensive electricity wise. Saving pump life? That's questionable. Pumps require more energy to start, and it's more stress on them to start than to run continuously.

When I start my aeration system, I just let 'er run. They are rated for 20,000 hrs before needing to put new vanes in them.

I bought my pressure relief valve from McMaster Carr for my Gast 0523. It is adjustable from zero to 20 psi. It always leaks a small amount, but is good insurance. IIRC I set it at 10psi - thereabouts. This is well enough above where my system operates. I had one of my three lines clog once and the new operating pressure was still lower than my pressure relief setting.

McMasterCarr part # 48935K25 - Adjustable Pressure- and Vacuum-Relief Valves for Air and Inert Gas, 440C Stainless Steel Seal, 1/4 NPT Male

The Gast 0523 wants to operate below 10psi for better life. It stalls out and sounds horrible at 20 psi (don't ask how I know).

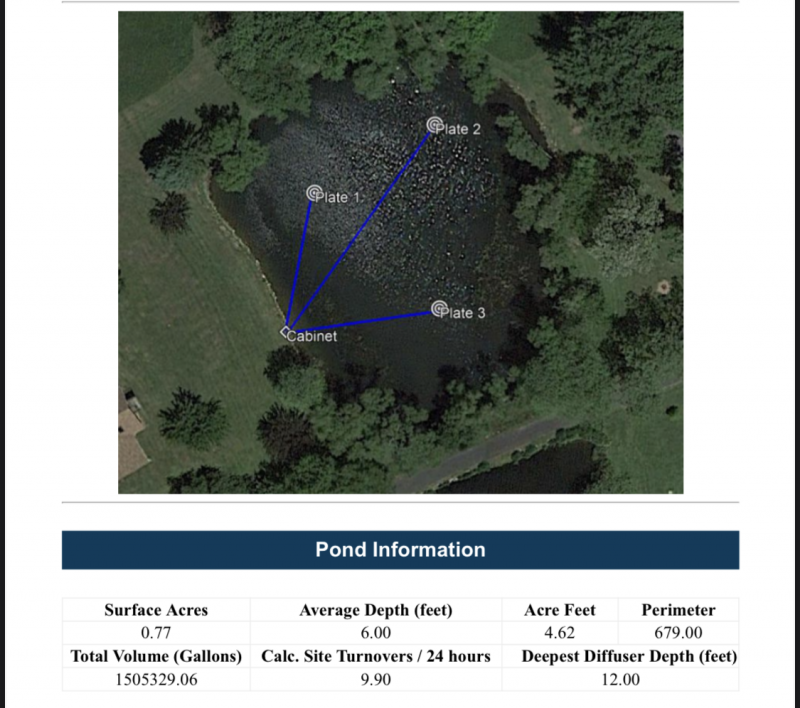

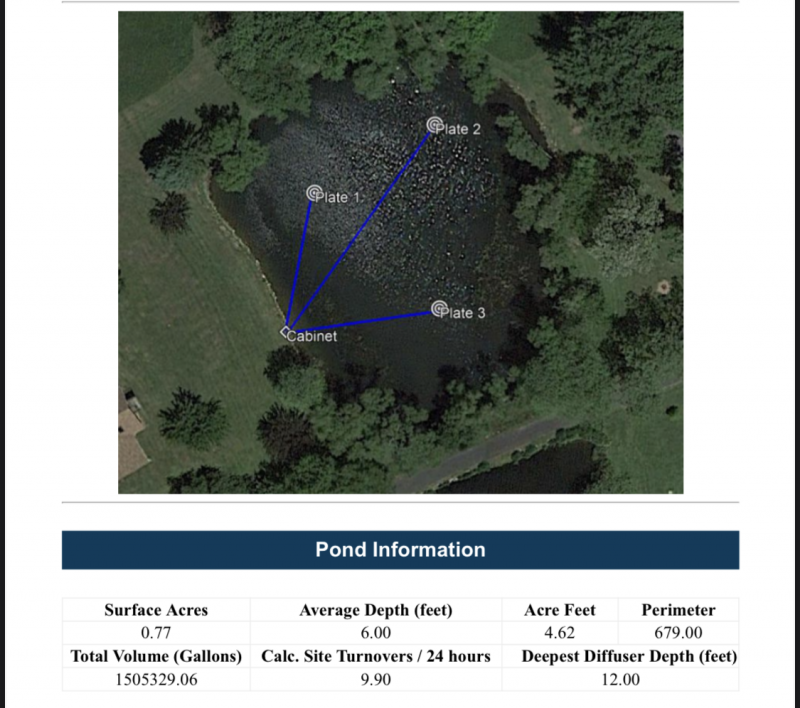

Inquired with pond guy over the weekend and this is what they sent back. Is this really necessary? It says the pond will turn over 9 times. Set up costs over 3k