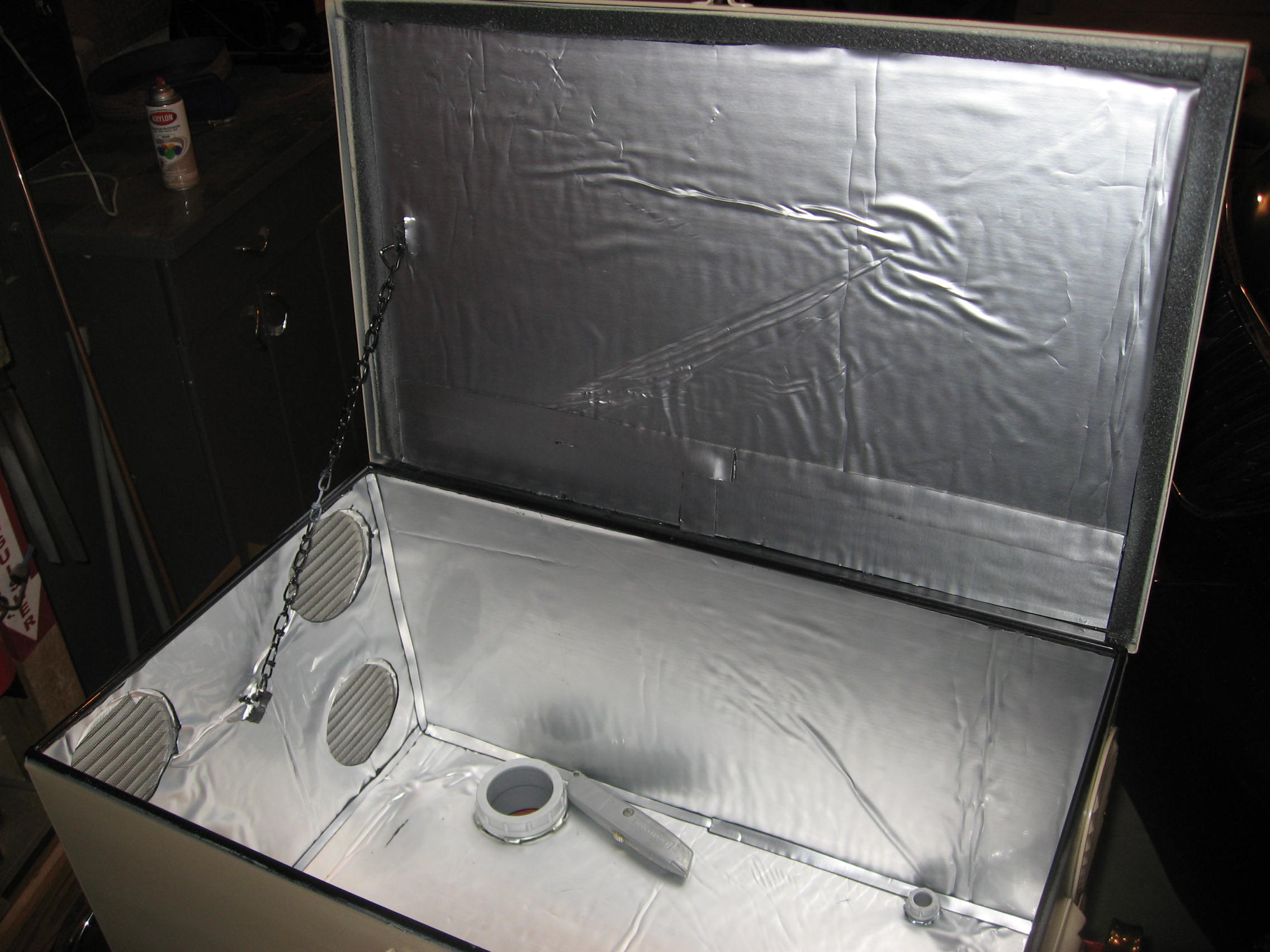

I don't know much about aeration, but it looks like you've got most of the pieces together. Just curious, is that box where your pump will stay? If so, what about venting to keep it cool? I couldn't see any vents or open places in the pics, so you may have them there, but I just didn't see them. I think that's a key factor in pump longevity.

It will be just like this when done.. Except mine will only cost about $100. Also im painting it the same color as my Moultrie Feedcaster..

Don't tell me you've got a louver punch! (and equipment with enough tonnage to use it)

My brother in law has everything for sheet metal.. I'm not sure if he'll be able to use it with the box already built. I could buy the box built cheaper than he said he could build it for.. The box is a tradesman off amazon $80 delivered.

Nevermind that, he sold his louver press.. He said it was junk anyways.. So Now i think I'll just use and hole saw as cut holes in the bottom and screen them..

You couldn't have used it on a pre-made box anyway. Punch holes in the box, put screen wire over the holes and install little awnings over the holes to prevent rain from entering. The screen is to keep wasps from calling the box home.

Good louver punches are hard to find and expensive.

He said his was an older one but still a cheap POS.. I was thinking holes in the bottom so I wouldn't have to worry about rain.. Thoughts?

Ok question for the pros.. I have both quarter inch valves and half inch but they both have the same size hole going through the valve.. Does this restricted hole affect my airflow and what should I use?

Holes in the bottom are a good idea providing that the box isn't sitting on the ground. A few holes up near the top will help with flow thru ventilation. Compressors generate heat and you want to get rid of that heat ASAP.

I would make sure that any valves that I used are the same I.D. as the air line or larger. I like the full flow ball valves.

So I need a valve with a 5/8 hole? Ant suggestions?

You probably could get away with 1/2" full flow ball valves (1/2" i.d.) but I wouldn't go any smaller. There aren't any 5/8" Ball valves, so you'd have to bump it up to 3/4". I believe a 5/8 hole is roughly 60% larger than a 1/2" hole (area wise). While a 3/4" ball valve is overkill, I don't know what the I.D. of the fittings are that you need to get back to 5/8" I.D. air line.

I found some.. They say 1/2" on the side but the hole measures 5/8".. I'm gonna run in sweated hard copper (free).

It will be just like this when done.. Except mine will only cost about $100. Also im painting it the same color as my Moultrie Feedcaster..

Boy, that looks really nice, BGK!

Thanks Todd..

Anyone got pics of manifolds?

Running it in copper will be nice! I'd run a 2' or so section of flexible line before the compressor hits the hard copper to keep the vibrations away from the copper. That sounds like a great system! Look on sites that have Pex tubing manifolds for ideas.

I was actually thinking of running a 18" section of braided stainless to a manifold that I mount on the back wall of the box.. Then I can take the pump out without disturbing the manifold and lines or vise versa..

That'll work too! Swivel ends on the braid.

Yep.. What's your thoughts on quick release ends, make it even easier to repair/clean..

Hey Guys,

Starting to get my pieces together.. Still on target for a spring startup.. Tell me what you think..

Looks good - congrats!

Things are beginning to come together ….

Here’s a idea for a compressor cover that has served me well.

Igloo Po-Boy cover- more than six years old – no fan - only vent holes - motor running strong 24/7 – no pressure loss!

¼ hp Gast roatary vane compressor from Bill Cody

Yep.. What's your thoughts on quick release ends, make it even easier to repair/clean..

Can you get them with a large enough I.D. and not break the bank?

George, that looks like a nice set-up. Good idea putting it upside down, I've had coolers sitting outside in the rain right side up and they've ended up with a couple of inches of rain in them with the lid closed.

Think your right.. For the cost its not worth it. I can handle a couple wrenches quite well.. I picked up all my copper fittings/barbs and valves.. What do you guys recommend for a blowoff valve, and do you think i need a valve to shut off all 3 valves like main shutoff? How many pounds should my pressure guage read up to any suggestions on brand?

Also Cool set up George1, where did you get those vents?

How many pounds should my pressure guage read up to any suggestions on brand?

Funny you should ask. I was just researching it today for another member here. His windmill system operates up to 25 psi, so a gauge 0-30 would work fine. Our esteemed Mr. Cody said liquid filled (glycerine) gauges weren't a necessity, but for the $3 difference I'll get 'em.

Liquid Filled Dry

Also Cool set up George1, where did you get those vents?

Either Home Depot or Lowes - both circular and rectangular. Probably ten bucks using discarded cooler.

Can't believe the little Gast compressor has survived rain and 100 degree plus Texas summers in this type cover - it's a winner.

Good luck on your aeration system - it's the life blood of a pond

The valve, guage and filter, as well as plans for assembly were provided by Bill Cody.

He's the master for DIY aeration systems.

Bill has helped me out extremely.. I cant thank him enough.. He kinda just hides in the shadows then hits you with great knowledge when your least expecting it.. Very nice guy too..

BGK, make sure you get to the Pond Boss Conference in April down in Branson if you want to really learn more of what Bill knows...the dude is a true phenom!

I also fond out he can squeeze himself through a 5" gap between my truck and his house!...lol

I also fond out he can squeeze himself through a 5" gap between my truck and his house!...lol

You sure it wasn't because that little legal blindness thing you've got going on caused you to smash the poor guy against the siding during a delivery?!

Hmmmm....It WAS on the left side of the truck (same as the bad eye).

Or maybe it was just because you were letting Mason drive again!

Mason the driving PB mascot --

Wellllll, I'm not really sure you can call what he does "

driving" . . .

But, hey, ole' Mason is a gamer!

A lotta insider (joke) trading goin on here..

A lotta insider (joke) trading goin on here..

Rex delivered a rescue dog (Mason) from down South to Ohio and had an interesting trip.........

Will the box be put in place on the boards like that, (attached to them of course)?

Yeah the box will be mounted on top of the 4x4's on top of a concrete pad.

BGK, make sure you get to the Pond Boss Conference in April down in Branson if you want to really learn more of what Bill knows...the dude is a true phenom!

I also fond out he can squeeze himself through a 5" gap between my truck and his house!...lol

What the date again?

I'm checking with the boss now... Bad think is I doubt ant of my bum friends will have enough money Togo so I might have to make a solo flight..

Ok so checking with the boss might of been a bad idea.. NOW SHE WANTS TO GO WITH MY NEW BABY (will be born feb 9th)..

Update on aerator..

Got legs on the box

Got intake filter made up fr compressor

Wired up compressor

Got all the pieces for manifold except relief and gauge

Got free relief and gauge coming next week

Bought paint for box wrong color (color blind bad)

How many PSI should the relief valve pop at.. Or should I just get the variable relief valve..

What's the operating range (psi) of the diffusers? I'd set it slightly under max pressure for them.

If I do that it'll pop right away..

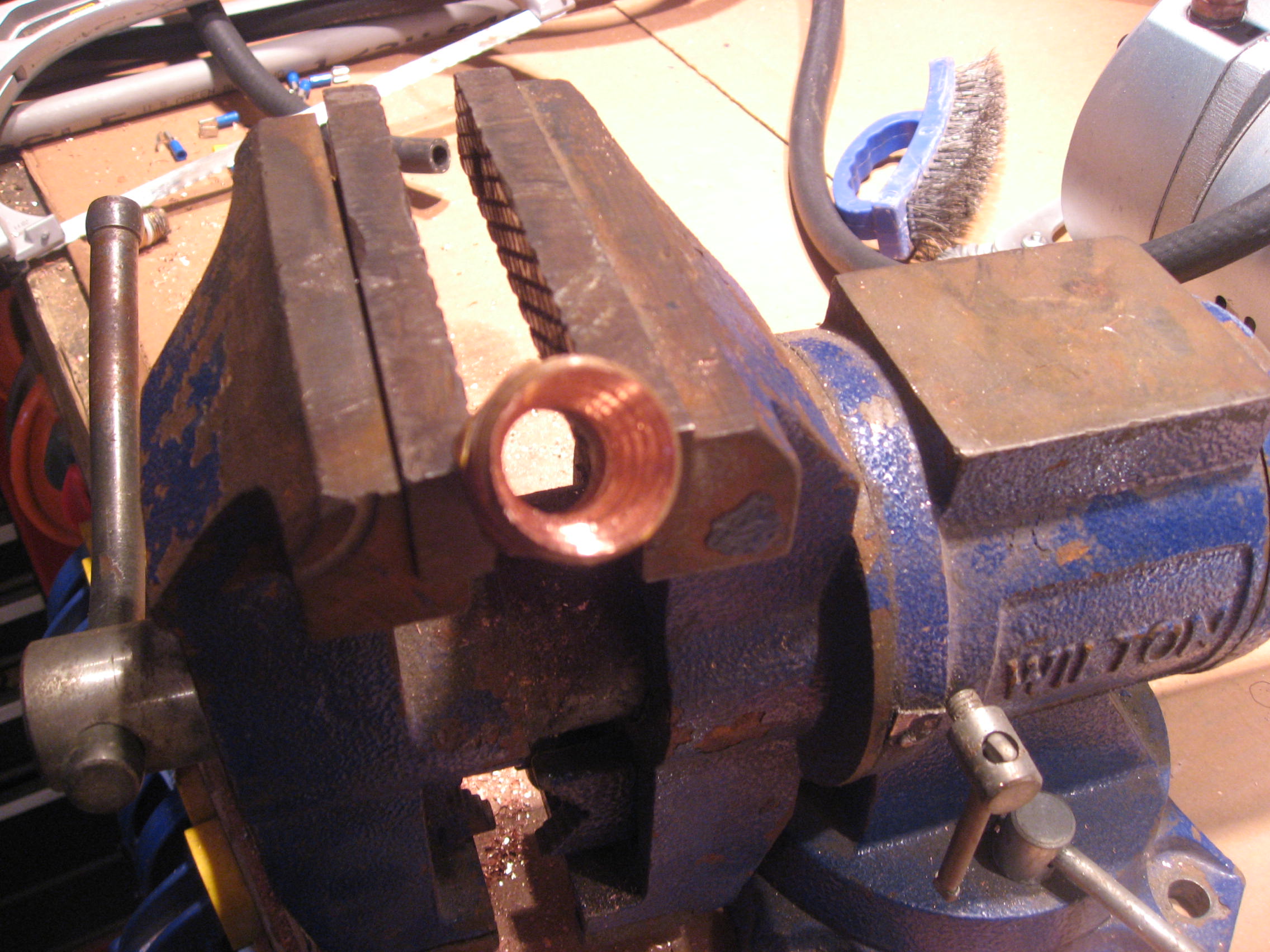

Couple more pics. Assembled the diffusers, retapped my compressor head too fit 1/2" NPT instead of 3/8" NPT threads..

IMO your air filter is way too small for that high volume compressor (3/4hp, 10cfm). That air pump is moving about 106,000 gallons of air per 24 hrs. There is quite a bit of dust and dirt in every million gallons of air. The small filter you have on that pump will plug up pretty fast depending on the air quality going through it. Check that existing filter at least twice a year for free air flow. A clogged filter reduces efficiency of the 'pump', thus diffusers are less efficient and move less water.

Pressure relief valve setting can vary depending on how deep the pond is and the type of compressor. As a general rule for a rotary vane, Gast Mfg sugggests relief valve setting to be at 15psi. Adjustable pressure relief valves usually start 'weaping' air at about 2-4 psi before full air release; depending on several factors.

It would have been easier and quicker to put a 3/8" close nipple & bell reducer (3/8"x1/2") on the pump instead of retapping the head of pump. Both will be just about as efficient for air flow for that short distance. You will see a more efficiency air loss when that air filter begins to clog compared to enlarging the outlet pore of the compressor.

Looking good. A buddy that runs a small job shop (machine shop)has filters on the air inlet openings on his compressor room. He said he has had less problems with dust since he installed them. He changes them out every couple of months.

I might get one of those outter socks that slip over the filter aswell, Just too be safe.. Also on the box I'm gonna paint those vents same as the box, forgot to mention that, don't need that flashy aluminum in the field

Well got some more work done on the box. Painted, vents completed, conduit attachments put in, padded the bottom, All i Have left to do is eggshell it, mount manifold, mount compressor, and electrical junction box.. Tell me what you guys think.. Not bad for a po-boy job. Beats the 250-600 price tag of the prebuilt ones.. I think i might cut the legs off to keep it close to the ground. I was thinking leave them long so i wouldnt have to bend down to work on things, but if i leave them long it will look like a sore thumb sticking out next to my pond, maybe i'll put it like it is and landscape around it. I dont know.. Spring will be here before we know. Im gonna use air conditioner/condensor pads for my diffusers. The bottoms have ribs that i could drill through all of them and pour concrete in and the concrete would connect through the holes really attaching it to the bottom of the pad. Also giving me a solid weighted base then i could just attach my diffusers with stainless strapping and stainless tap cons. The pads are about $25 apiece and my birtdays this friday so i told my Wife to get me 2 for my birthday then ill buy the last.. Coming together nicely. Still need to figure out a good line/hose plan thats next. Also i have to run electric a few hundred feet to where i wanna place my compressor.. lots to do and times flying buy. On a side note i picked up a moultrie game feeder 30 gallon plastic feeder, they were on clearance for $90 i had $75 gift card from my dad so about $20 i got it for. Im just gonna solid mount it on a post out in the pond and see how it works out.. Well theres my novel enjoy..

That looks really nice, BGK. Remember that you are contractually obligated (it's in the fine print of the member sign up when you joined!) to keep us posted on this project as it progresses, up to and including final installation out in the field.

Im trying Todd. So far ive done a good amount of pic taking. Hopefully ill be able to take some pics of my fish growing too, just to make this work and money worthwhile..

Also thats 3 coats of clear making her shine like that.. LOL

thanks guys was hoping my sound deadner would come in today. Didnt happen.. What these chumps at fedex cant drive through a foot of ice and snow to get me my stuff lol. Where can i get a good deal on fans for cheap that will hold up to the heat also 230v. Im getting closer to just breaking down and buying them from greg but i thought i could find them cheaper, and he'll probably prove me wrong again and maybe ill just start listening to what he says lol

Also milled this fitting out to keep my pressure down on the compressor.. A little secret someone let me in on.. Keeps the compressor from working to hard and wearing prematurely.. Just a little trick thought you guys might like to see..

Youve been cleared for "takeoff" !! Are you pulling air in from the bottom or pushing air out thru the bottom with the fans ?

Im pulling air in from the bottom... Reason being, If i suck it from the bottom i dont have to worry about sucking in water and it will blow water away from the vents. The fans are not installed yet just setting in the bottom im making a little frame that will hold a furnace style filter over the fans to fight dust even though it will be mounted on concrete..,

It looks like something futuristic with that sound deadner. I still need some hydraulic flex line to connect the pump to the manifold, also need to wire in my fans. Another major project is trenching power from my house down to it thats gonna be 100-200' havent even began to measure that yet.. Definately still on target for the spring start up.. Oh yeah need to make my bases for the diffusers yet too..

Couldnt of done it without your help Ted, also Bill Cody helped to..

Thanks Guys

Got any suggestions?

Also the fans will be mounted like this probably.. More symetric.. I must have some kind of OCD..

very nice work, i was lazy and ordered mine from ted. and my shop was only 150' away so its mounted in the headed shop.

Let me here some diffusers base/pad ideas? I've got some ideas but there kinda expensive I'm a cheapskate and have 3 kids..

BGK, System is looking good! I used bread racks, they held three 9" diffusers perfect. Here is the link to some pics. You can find these things at any grocery store sitting outback. If you cant find bread racks, milk crates, or plastic plallets. All there doing is sitting on the bottom of the bond, who cares what it looks like. I liked the bread racks because i put river stone between them for weight and zipptied them all together.

http://www.pondboss.com/forums/ubbthreads.php?ubb=showflat&Number=248108#Post248108

I seen your setup RJ22 and i like it, thing is my ponds 20-30 yrs old and has never been aerated. I have i know for sure atleast a foot of muck in most places. So i need a fairly big SOLID base to set my diffusers on to keep them from stirring up muck and making muddy water..

Thanks BGK. what about a large rubber made tote like 2'deep x4' wide x3'high (like the big ones you store fake christmas tress in)put some weight in the bottom. that way if it did sink into the muck a foot or 2 the diffusers still would be inside the tote and the top rim of the tote would be 1 to 2 feet above the top of the muck? Cheap to at 10$ to 15$ bucks a peice. Just and idea

I found something id like to use, But the shipping on it kills me. there like $25 each, Air Conditioner Pads flipped over and filled with concrete (50lbs). They are real thick plastic that would last forever but they want like $100 for shipping 3 crazy.. Im gonna figure out a way to get that shipping lowered..

Update: Got my trench in to run power over to the compressor and dock area.. 500' OUCH...

Any more updates? Pictures?

Latest update:

Wire is buried from basement to location (575'). I need some help now.. I have (3) fans and the pump all in the pump house.., I wired the all together in a junction box? Now for the house end of it. What do I do? As far as my panel box? Or I'm thinking I have to come out of the panel box to an outlet so I can put an in-line timer in.. What breaker should I use.. My pump only pulls like 5-10 amps can't remember exactly off the top of my head? Can someone guide me??

BGK, as far as the wiring goes... what size wire did you run? the size of the breaker that you need depends on the amount of amps that you intend to use...but then also you need to run the appropriate sized wire for that amount of amperage and take into account voltage drop over long distances.

okay so normally a 15 amp circuit would call for 14 gauge wire...a 20 amp circuit would call for 12 g wire. (this is for copper wire btw, not aluminum) you said you have a 575 foot run??? im not an electrician but as the run gets longer it is a good idea to bump up the wire size a bit to help prevent a voltage drop. in you case that is a real long run so you should bump it way up.

here is 2 links to voltage drop calculators

http://www.nooutage.com/vdrop.htm http://www.elec-toolbox.com/calculators/voltdrop.htmassuming you are running copper wire in pvc conduit both suggest #4 wire...yikes that is some big wire.

if it was me id put a new 20 amp breaker in your electric panel and run 4g wire..jmo

if you run it off an existing outlet...lets say a 15 amp, if the pump and fans pull 10 amps while running then that doesnt leave you much power left in that 15 amp circuit, if you use anything else in that circuit with 5 amps or more of power you will flip the breaker.

justin

BGK, Justin's figures are accurate. "BUT" if you plug in #6 to the VD formula it comes up just a shade over 5% VD. With everything being said you want the smallest amperage (15 or 20) that will addequately support your load without nuisance tripping all of the time. which ambient temperature swings based on the time of year will cause your amperage to fluctuate slightly.

So alot rides on the size of wire you ran.

Yeah I already figured all that out I ran most of the run in 10ga then about 200' in 12. My pumps only gonna pull 4-6 amps can't remember exactly.. Im only gonna run a 15 amp breaker after talking to a couple electricians I work with.. All my wire was direct burial.. Also I ran 10-3 and 12-3 I plan to run a hot of my power feed to the pump and a neutral back to a separate 15 amp breaker for an external outlet on the side of my compressor house.. Not exactly code but it'll be alright.. The pump will only be running at night so I won't be pulling extra juice on one leg if I plug in a radio during the day..

Next question I need a good 240v timer?? Anywone??

Slyvania makes an inexpensive, reliable timer here...

Timer

Thanks rainman.. Heard anything on them gills,?