Aquapro ADF75, Replace battery with power supply? - 05/06/18 10:01 AM

Hello all.

I bought a used ADF75 off craigslist.

The timer is the F2 model.

I replaced the 12V battery with a new one (12V,8ah.) The battery indicator status shows all but one bar. My multi meter shows 12.9V.

When I run it in test mode, only the top spinner plate runs. However, if I hook my battery charger to the battery (2.5AMP), Both the upper and lower spinners run.

I have read that only the top spinner running indicates a weak battery.

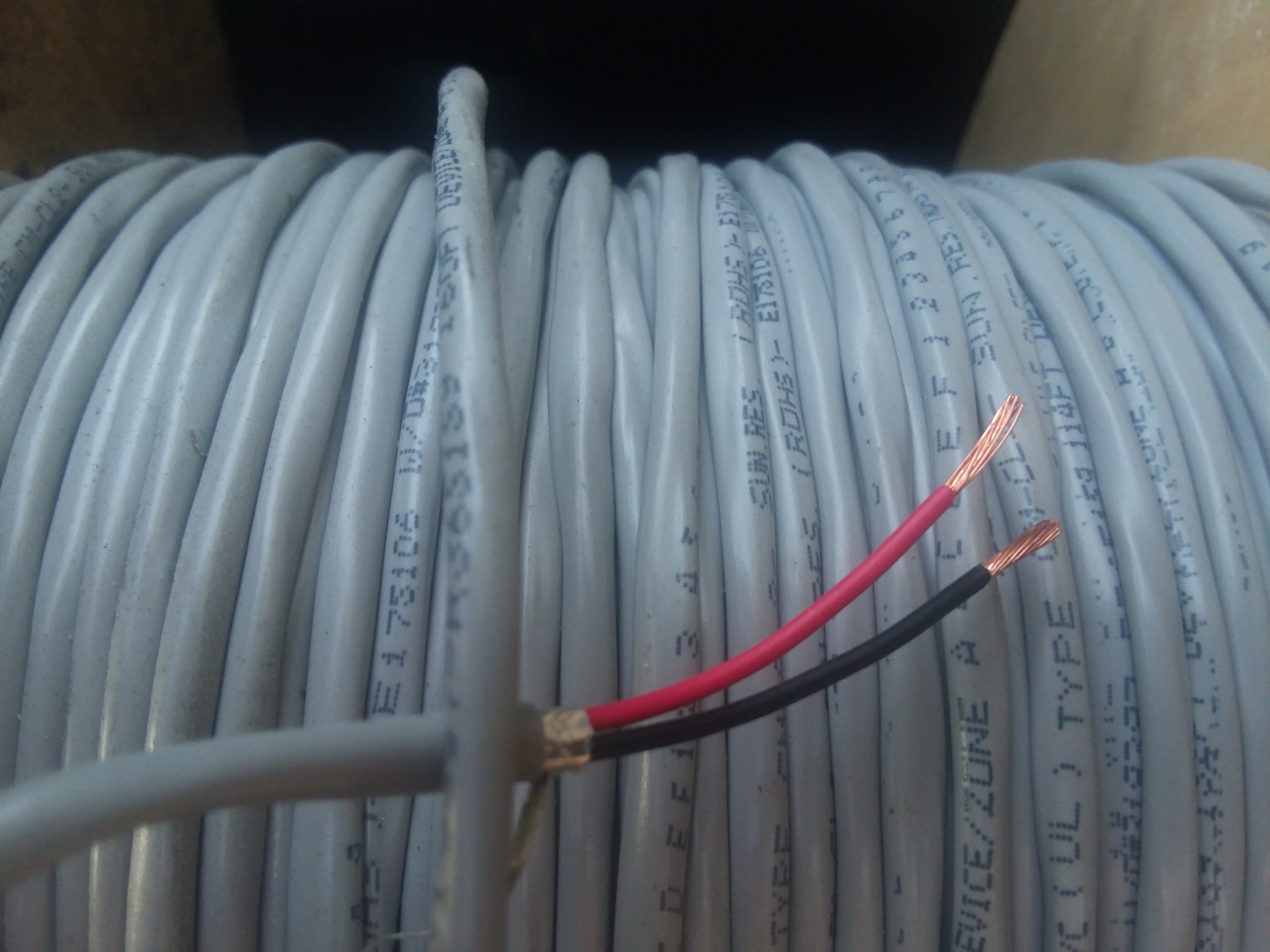

I have access to 115V A.C. power at the feeder. I am considering replacing the battery with a 12V DC 5amp (7 AMP surge) power supply.

Here are the motor specs:

1/35 Horsepower RPM 2942 @ 2 amps Draws 4Ĺ amps at startup, 3 when running.

Does anyone have experience with such a project? Do you think I need more amps?

The duty cycle is short (1 second feed time.) Motor startup is the same draw, regardless of the duty cycle.

Thanks guys!

Btw, this forum is a wealth of knowledge.

It's amazing how much information is here!!

I bought a used ADF75 off craigslist.

The timer is the F2 model.

I replaced the 12V battery with a new one (12V,8ah.) The battery indicator status shows all but one bar. My multi meter shows 12.9V.

When I run it in test mode, only the top spinner plate runs. However, if I hook my battery charger to the battery (2.5AMP), Both the upper and lower spinners run.

I have read that only the top spinner running indicates a weak battery.

I have access to 115V A.C. power at the feeder. I am considering replacing the battery with a 12V DC 5amp (7 AMP surge) power supply.

Here are the motor specs:

1/35 Horsepower RPM 2942 @ 2 amps Draws 4Ĺ amps at startup, 3 when running.

Does anyone have experience with such a project? Do you think I need more amps?

The duty cycle is short (1 second feed time.) Motor startup is the same draw, regardless of the duty cycle.

Thanks guys!

Btw, this forum is a wealth of knowledge.

It's amazing how much information is here!!