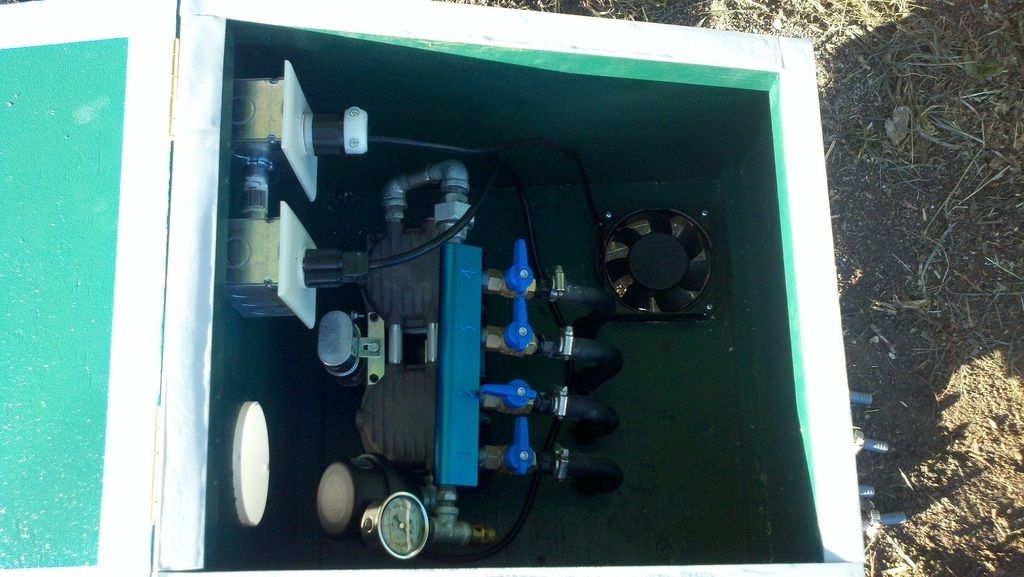

Here's my DIY compressor cabinet I built back in May, 2012 and still holding up fine. If you'd like more details let me know.

How about a BOM (Bill of Materials) and a write up on how you built it? Or a link to it if it's on here somewhere?

Is there a screen over the fan on the bottom?

Looks good!!!

Have you ever had snow get high enough to cause air flow problems thru the cabinet in the winter?

+1 I like it!

Thanks guys!

Are you sure you want all this???

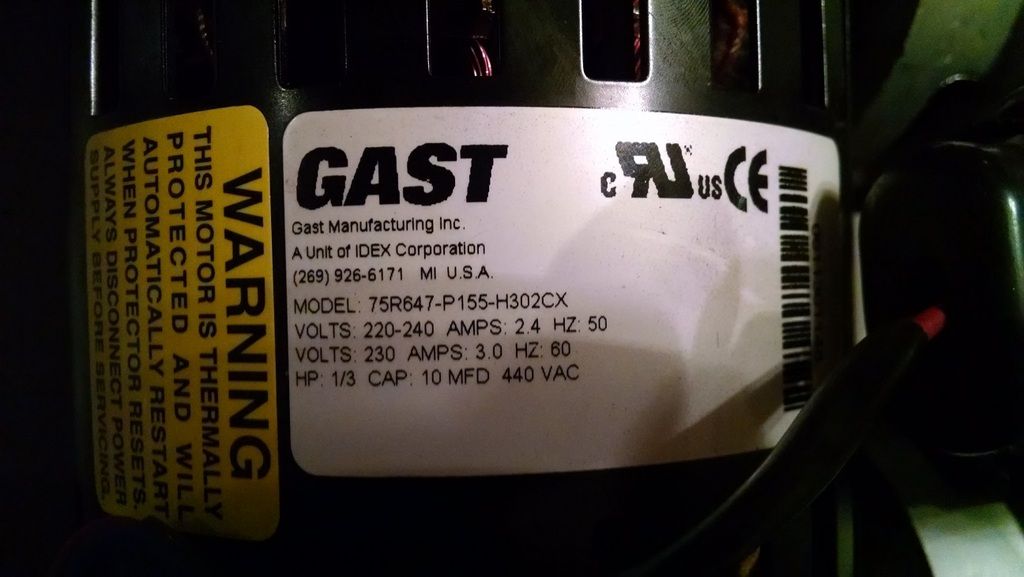

As far as a BOM, I don' know the exact dimensions of the box off hand, but the pump, manifold and fan came from the late Ted Lea. Once I received those I started on the cabinet, making it just big enough to house everything.

I'm not a craftsman by any means, more of a challenge-seeker so there's a lot of WAG's involved in most of what I do and/or build. No written plans, just an idea and "go from there".

I believe I used 3/8" ply but may have been 1/2", and I didn't use treated ply as I knew I would be sealing and painting it, and used 1x2's as inside perimeter supports and also for the hinged lid.

I'm also guessing I didn't go through a full 4x8 sheet of ply and maybe 20' of 1x2. Other than that the materials consisted of:

Screws

Wood putty

Paint

Dryer vent

PVC that I buried the electrical in

2-240v outlets and gang boxes

I have a screen over the dryer vent intake but not on the underside of the fan as it usually runs 24/7. Although I'm not running it this winter so I covered it on the inside.

I've not had snow high enough to cause air-flow problems but if I had to do it again, or if I knew I'd be there long enough, I would raise the cabinet due to the dust on windy days likely being drawn in, due to close proximity of the ground.

As far as the manifold, it's very light-weight aluminum so it's not like there's a lot stress involved coming from the airline to the motor. And from outside the cabinet I connected heater hose from the weighted tubing before it enters the cabinet and connects to the manifold. I also cut oversize holes in the bottom of the cabinet and inserted small pieces of larger heater hose as an insulator due to any vibration and not wanting the airline heater hose rubbing directly against the wood. This also relieves any tension from where the airline attaches to the manifold as it's a very tight fit coming through the bottom of the cabinet.

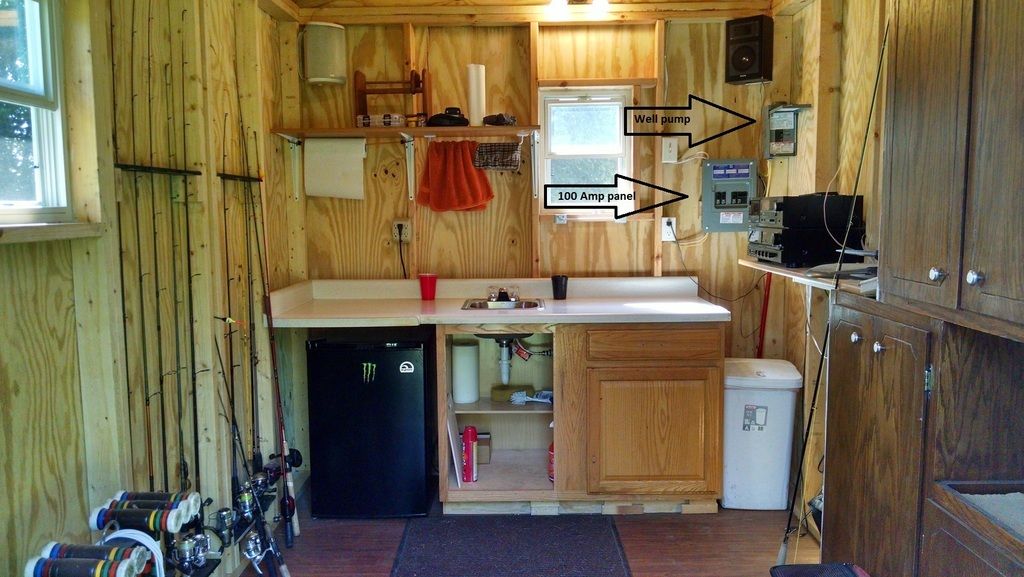

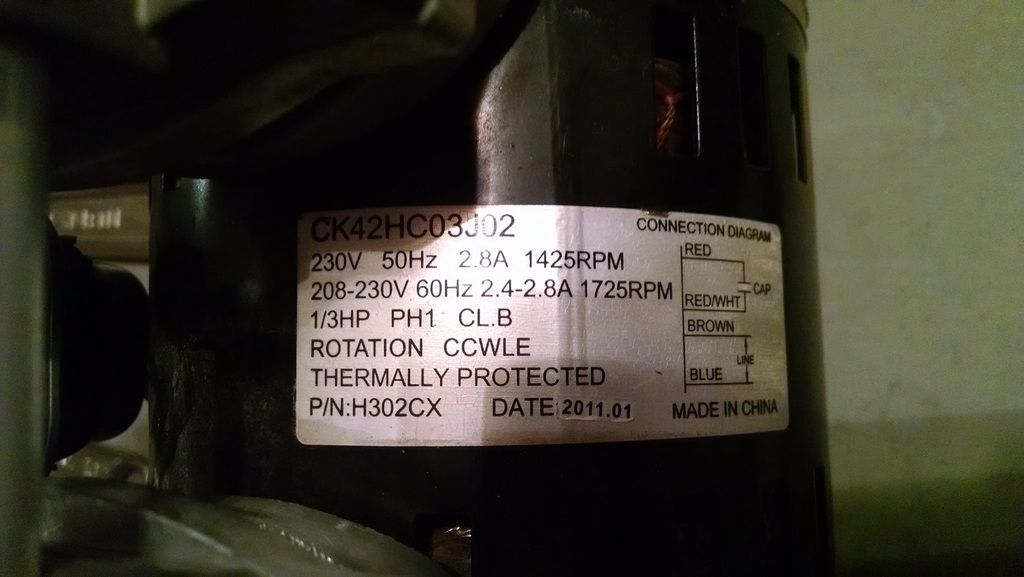

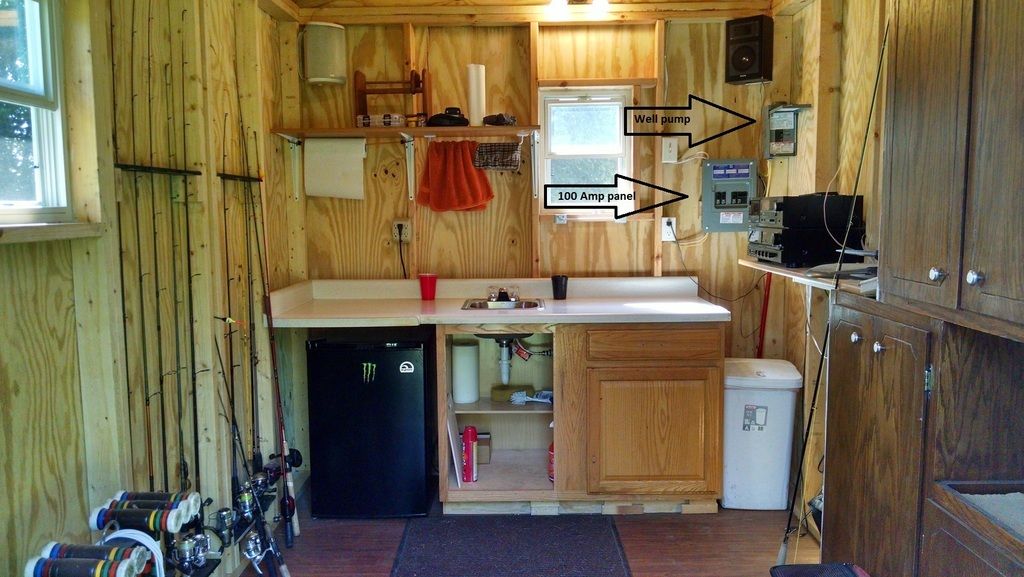

My system is 240v and since building the fish house, I ran the Tri-Plex from the power pole directly to a 100A distribution panel in the fish house. The panel has breakers for the 240v compressor pump and lights and outlets for the fish house. And there's another panel for the well pump.

Here's the pics of the cabinet when I built it:

As I'm sure that's more information than any of you really wanted, if you have any more questions, just let me know,,,,, but beware as you know I can get wordy

PS - So much credit on building this cabinet goes to the late great Ted Lea. it was with his guidance that the air flow from the fan and vent passes over the motor, using heater hose to enter the cabinet, and to "insulate" it to prevent rubbing.